Sounds like a task for leather artisans? However, you can do it too. It is not as hard as you think. Indeed, dyeing leather is an easy task. With the right tools and the right guide, you will be dyeing leather in no time. Whether you are planning to dye an old leather bag or working on an unfinished leather yourself. Furthermore, dyeing leather is a matter of preference. Therefore, trial and error is a big part of the process. You have to be patient and test for the best color will suit your taste.

P.S. you cannot dye black leather but you can dye other leather colors into black.

Key Takeaways

- Proper preparation, including cleaning and rehydrating the leather, is crucial for successful dyeing

- Different types of dyes (alcohol, water, and oil-based) offer various benefits and drawbacks

- Multiple thin layers of dye typically yield better results than one thick application

- Post-dye conditioning is essential to restore moisture and maintain leather quality

- Safety measures, including proper ventilation and protective gear, should not be overlooked

Leather Dyeing Safety Measures

When engaging in the process of dyeing leather, it is paramount to prioritize safety measures to ensure a smooth and risk-free experience. First and foremost, always work in a well-ventilated area to prevent the inhalation of harmful fumes from the dye and any associated chemicals. Wearing protective gear such as gloves, masks, and goggles is essential to safeguard your skin and eyes from potential irritation.

Additionally, consider using an apron or old clothes to protect your garments, as leather dye can stain fabric irreparably. Before starting, it is wise to conduct a patch test on a small, inconspicuous area of the leather to check for any adverse reactions. Lastly, make sure to keep your workspace organized and free of clutter, and properly store all dye-related materials out of reach of children and pets to maintain a secure environment.

Preparation Requirements

Workspace Setup

Before we talk about how to dye leather we must get everything we need ready first. First and foremost, you will need space. Space that is enough for you to place the leather in a clean and cool area. Next, is the things that you will need. You might need gloves and an apron to protect yourself and your clothes from stains and unwanted spills. Likewise, you might want to cover or line your workspace to protect it from stains and spills. It will get messy every time you try to dye leather. Especially for those who are dyeing their leather for the first time.

Ventilation

Ventilating a room, although is not a must, is necessary. Fumes from the oil dye are harmful if you are exposed to it for a long time without ventilation. Cracking open a window and turning on a fan will do the trick. Make sure to get proper ventilation before you dye any leather. Not only will it keep you safe but cool when you work as well.

The Dyeing Process

| Step | Action | Tools / Tips |

|---|---|---|

| 1️⃣ Prep | Clean + deglaze + rehydrate | Dry cloth, deglazer, oil (no conditioner!) |

| 2️⃣ Cut Dye | Dilute for muted look | Use same base: alcohol, water, or oil |

| 3️⃣ Apply | Multiple thin layers | Cotton rag (flat), Q-tip (edges), dry between coats |

| 4️⃣ Condition | Restore moisture + seal | Leather conditioner, optional finisher, dry overnight |

Pro Move: Thin layers = even color. Used on Dagny Weekender for rich, lasting finish.

Step 1: Preparing to Dye Leather

Cleaning

The first step in dyeing any vegetable-tanned leather is to properly clean it. To properly clean leather for dyeing, you will need to wipe off any lingering dust and grime on the leather. Wipe it off gently with a dry smooth cloth.

Next is to get rid of any body oil that you may have left when you were using the leather item. You may either wipe it off with a soft clean cloth. Some use a deglazer to thoroughly and completely remove any oil that may have been left off on the first wipe.

Cleaning is an important step in preparing to dye the leather. This is because any dust, grime, or oil will affect the coverage of the dye. At the same time, the dye will have a hard time penetrating the leather. It may leave off an uneven dye to the leather. What is worst is that it may not hold on to the leather if there is any lingering dust, grime, or body oil left in the fabric.

This critical preparation step is supported by research in leather treatment, which confirms that ensuring the leather is free from dust, grime, and body oils is foundational, as any residue can hinder the dye's ability to penetrate effectively, resulting in uneven coloration (Song et al., 2017; Mirzamuratova et al., 2024).

Rehydrate Your Leather

The last step in preparing your leather for dyeing is to rehydrate it. Using the oil of your choice apply small dabs to the leather. Spread the oil evenly and thoroughly by gently wiping it with a smooth clean cloth. Although this step is not necessary, it is recommended by other sources. The reason is that hydrating the leather will make it receive the dye better. Likewise, it is important to remember not to use any leather conditioners before dyeing. This is because the conditioner will be preventing the dye from penetrating the leather.

Real-World Application: The Dagny Weekender Experience

At Steel Horse Leather, we've applied these precise dyeing techniques in crafting our signature Dagny Weekender bags. During the development of this full-grain leatherweekender, we discovered that proper leather preparation was crucial for achieving the rich, sophisticated finish our customers expect.

Each bag requires meticulous cleaning and precise rehydration to ensure the dye penetrates evenly across the large surface area, particularly important for a travel bag that needs to maintain its appearance through frequent use. The multiple interior pockets and removable shoulder strap components require special attention during the dyeing process, with careful application around stitching areas and hardware attachment points.

Step 2: Cut Your Leather Dye

To "cut" dye means to dilute the dye. This step is important in achieving the color you desire for your leather. Applying dye in its full and concentrated strength will result in a bolder color. Likewise, for a more muted or antique finish, you may want to dilute your dye and apply it on thinner multiple layers.

Types of Leather Dye

Leather Dye And Its Different Bases

Leather dye has many bases. The most common leather dye bases are alcohol, water, or oil. If you want to dilute your dye you may want to know what its base is. This is important because you can only add the base of the dye to dilute it.

Step 3: Apply The Leather Dye

Use soft cotton rags to apply the dye on the flat surfaces. Likewise, use the q-tips to apply the dye on hard to reach places such as the corners and edges. Apply the dye as many times as need until you reach your desired saturation. Always let the dye dry before applying another layer. Never continue working while the dry is still wet as it may leave serious smudging. Upon reaching the desired color leave the leather to dry then proceed to the final step.

Research on leather dyeing techniques emphasizes that applying multiple thin layers enhances color depth and uniformity while allowing better control over saturation levels (Mirzamuratova et al., 2024). This layered approach is far more effective than attempting to achieve your desired color in a single application.

Step 4: Conditioning The Leather

Congratulations! You have just dyed leather. After exposing the leather with dye, it may dehydrate in the process as moisture is drawn out by the dye. It is important therefore to restore that lost moisture as soon as possible. Worry not, the solution is simple. The final step is to condition the leather. This will rehydrate and strengthen the leather fibers. Helping to ensure that it will last for a longer time. Leave the leather to dry overnight after conditioning it.

Studies on leather treatment confirm that conditioning products help mitigate any drying effects caused by the dyeing process, ensuring the leather remains robust and visually appealing over time (Mirzamuratova et al., 2024). This step is particularly important when using alcohol-based dyes, which are known to draw more moisture from the leather.

After conditioning the leather, some apply a leather finisher or a sealing. Aside from the conditioner, this will help protect and maintain the leather for a longer time. Although this is not necessary it is equally important as conditioning.

The Role of Water in Leather Dyeing

Water plays a crucial role in the leather dyeing process, acting as a key agent that facilitates the absorption of dye into leather products. When dyeing leather shoes or any leather item, it's essential to prepare the piece of leather with the right moisture content; tap water can be used, but too little can lead to uneven dyeing, while excessive moisture might dilute the dye's potency. Whether working with natural leather, grain leather, or finished leathers, properly wetting the leather surface not only enhances the dye's penetration but also ensures a smoother application, allowing for a more uniform color.

Moreover, the temperature of warm water used can significantly impact the dyeing outcome; it tends to open up the leather's pores more effectively, thereby allowing both water-based dyes and alcohol-based dye to bond with the hide more thoroughly. When working in a well-ventilated area, understanding the appropriate balance of water is vital for achieving vivid colors and that rich, deep color you desire in your leather dyeing project.

Importance of Drying Between Coats

The drying process between coats of dye is a crucial step when dyeing leather, as it serves multiple purposes that directly affect the final outcome. Firstly, allowing each layer of dye to properly dry ensures that the color sets uniformly and adheres to the leather material without any smudging or fish eyes. Using a blow dryer can help speed up the process, but avoid constant exposure to direct sunlight, as this can affect the depth of colour.

Additionally, drying between additional coats helps prevent the leather from becoming overly saturated, which can compromise its texture and durability. For larger surface areas or when dyeing shoes, the ideal drying time can vary based on environmental conditions, but a good rule of thumb is to wait at least 30 minutes to an hour before the next dye application. Whether you're working on a leather wallet or a pair of leather shoes, this patience pays off in achieving a professional finish.

Buffing After Dyeing

Buffing after dyeing is an essential step in achieving a glossy finish on your dyed leather. This process not only removes any excess dye that may still be present on the leather surface but also smooths out the texture, enhancing its natural beauty. To buff properly, use a soft cloth, horsehair brush, or soft cotton rag to gently work in circular brush strokes. For best results, you might want to apply a leather conditioner like neatsfoot oil or jojoba oil to maintain the leather's suppleness.

Before applying a protective layer of leather finisher, consider buffing the leather after allowing the dye to fully cure, typically 24 hours. This ensures a water resistant and resistant finish while maintaining the beauty of leather. For maintenance, you can use a damp cloth for cleaning and a dry cloth for regular buffing. Some leather crafters also recommend applying a coat of oil or leather paint as a final step to achieve that perfect shiny finish on their custom color projects.

Why Trust Our Leather Dyeing Expertise?

At Steel Horse Leather, our deep understanding of leather dyeing comes from years of hands-on experience crafting premium leather bags using traditional methods. One of our flagship products, The Endre Weekender, exemplifies our mastery in leather dyeing and finishing. During its development, our artisans perfected the technique of achieving a consistent, rich black finish that maintains its elegance while withstanding daily wear and tear.

Our expertise extends beyond theoretical knowledge to practical application. For instance, when developing The Endre Weekender's signature black leather finish, we conducted extensive testing to ensure the dye penetration would be deep enough to maintain its appearance even with frequent handling of the bag's comfortable leather handles and straps. This hands-on experience with premium leather goods has helped us understand the crucial balance between aesthetic appeal and durability.

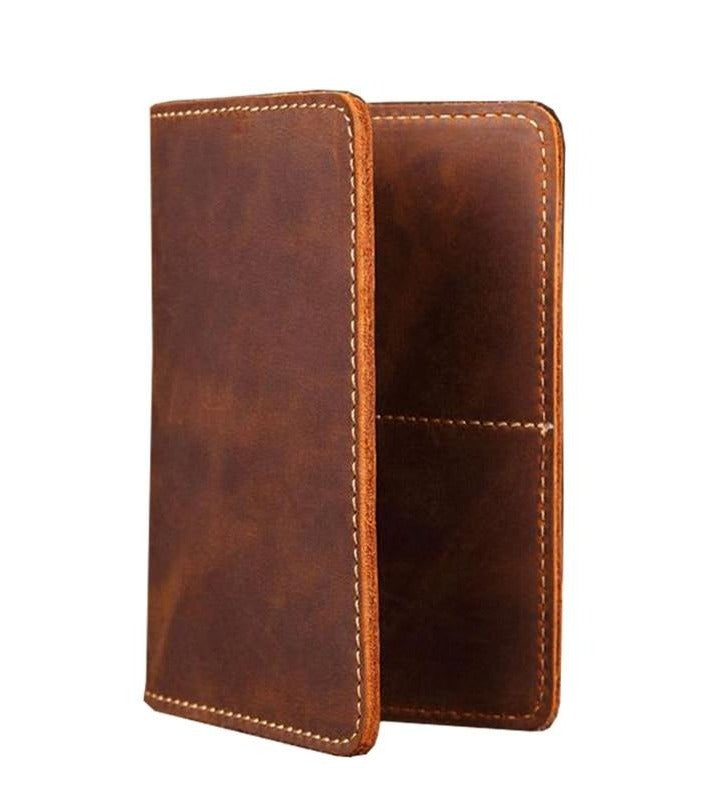

Through our extensive experience in vetting and selecting premium leather suppliers, we've gained comprehensive knowledge of leather properties, tanning processes, and how different types of leather react to various dyeing techniques. The cotton-lined Endre Weekender, measuring 20.4" x 12.6" x 11.8", serves as a testament to our ability to maintain consistent dye quality even across larger leather surfaces. Our artisans' obsessive attention to detail ensures that each piece, whether it's a small wallet or a full-sized weekender bag, receives the same level of care in the dyeing process.

Frequently Asked Questions

Can You Dye Any Color Leather?

You can dye most colored leather, but black leather cannot be dyed to a different color. However, you can dye any other color leather to black.

What Type Of Leather Dye Should I Use?

There are three main types of leather dyes: alcohol-based (deep penetration, vibrant color), water-based (less toxic, less penetration), and oil-based (good penetration without drying). Choose based on your specific needs and desired outcome.

Do I Need To Prepare The Leather Before Dyeing?

Yes, preparation is crucial. You need to clean the leather thoroughly to remove dust, grime, and body oils, then rehydrate it with oil before applying the dye. Avoid using leather conditioners before dyeing.

How Many Coats Of Dye Should I Apply?

The number of coats depends on your desired color saturation. Apply multiple thin layers, allowing each layer to dry completely before adding the next, until you achieve your desired shade.

Is Ventilation Important When Dyeing Leather?

Yes, proper ventilation is essential when working with leather dyes, especially oil-based ones. Open windows and use fans to prevent prolonged exposure to harmful fumes.

Conclusion

Leather dyeing is an accessible DIY project that requires attention to detail and patience. By following the proper steps of preparation, application, and finishing, you can successfully transform your leather items. Remember that practice makes perfect, and don't be afraid to experiment with different techniques and colors to achieve your desired results. Always prioritize safety and proper leather care throughout the process to ensure the best possible outcome.

References

Mirzamuratova, R., Bayramoğlu, E., & Kaldybaev, R. (2024). The effect of natural dyes on the strength of the leather. The Journal of Almaty Technological University, 146(4), 186-192. https://doi.org/10.48184/2304-568x-2024-4-186-192

Song, J., Kim, S., & Kim, H. (2017). Improvement of dye affinity in natural dyeing using terminalia chebula retzius (t. chebula) applied to leather. International Journal of Clothing Science and Technology, 29(5), 610-626. https://doi.org/10.1108/ijcst-03-2017-0029