Fake leather is a petroleum-based alternative to true authentic leather, known as synthetic leather or faux leather. While false leather has many of the same desired characteristics as genuine leather, to produce this material it is not required to hurt animals. Like real leather, fake leather is waterproof, supple to the touch. This cloth is therefore very stain-resistant and simple to clean. Although synthetic leather is less durable than actual leather, it is resistant to wear and cutting, making it the perfect fabric for taping in homes with children or animals.

Key Takeaways

- Fake leather offers a cruelty-free alternative to genuine leather while maintaining many similar properties like water resistance and flexibility.

- China is the world's largest producer of fake leather, with production primarily focused on PU and PVC-based materials.

- Environmental concerns persist due to the non-biodegradable nature of synthetic leather and its petroleum-based production process.

- New innovations in vegetable-based leather alternatives are addressing both ethical and environmental concerns.

- While more affordable, fake leather generally has a shorter lifespan compared to genuine leather.

Characteristics and Properties

The majority of synthetic leather producers produce this substance in the same hues as real leather however fake leather may be made in any color under the sun. Therefore, some producers try to distinguish their goods from the real market for leather by creating yellow, green, lilac, or even blue synthetic leather. Because fake leather is almost as excellent as actual leather at insulating body heat, it is used for outerwear, for example, leather jackets and coatings. It is frequently difficult to tell the difference between real leather and imitation leather unless you check it carefully. However, even the most inexperienced aficionados can generally distinguish between the plum and the genuine leather by touch. Synthetic leather is a plastic feel, which differs from real leather, the largest reason.

Environmental and Ethical Considerations

While animal rights advocates are boasting about false leather since there is no need to murder cows or other animals, environmentalists are complaining that synthetic leather does not biodegrade and hazardous chemicals are being released into the environment in the manufacture of this substance. However, in recent years some manufacturers have begun to produce synthetic vegetable leather, which apparently resolves both the ethical questions of real leather manufacturing and the environmental issues with fake leather production.

Synthetic Material Explained

Synthetic materials (also known as synthetic, fake, imitation, vegan, or PU leather) are synthetic materials that are leather-like, but not animal-like or hide-like. The synthetic material comprises natural or synthetic fibers, which are covered with or similar plastic polymers. Synthetic material is often produced from polyamide microfibers composed of polyurethane (PU), polyvinyl chloride (PVC).

Terminology and Naming Conventions

There is a lot of phrases for leather imitation. Some of them are false leather, fake leather, leatherette, synthetic leather, artificial leather, leather created man or skai. Artificial pelts are known as artificial pelts or artificial furs. A polyurethane coating instead of PVC coating is available in modern synthetic leather. Thus, the name PU leather imitation is employed. In areas of China, imitation leather is called PU leather, whereas in other places the Portuguese call it napa, and many different phrases exist.

History of Synthetic Leather

Presstoff was one of the original kinds of false leather and still stands in production today. This textile has been created in Germany and has been utilized extensively in WWII because of the tightly rationed usage of pure leather. However, Presstoff production never became very popular beyond Germany, and customers quickly preferred other leather options which had more desirable characteristics.

Early Development and Evolution

The development of Naugahyde in 1920 marked the beginning of Synthetic leather on the world fabric stage. The material was developed in 1892 by the U.S. Rubber Company. After years of diligent study, the U.S. Rubber experts have created this feasible leather substitute, originally utilized in handbags. For many years, synonymous with synthetic leather remained the brand name "Naugahyde." In many industrial uses through the 1930s, this material grew widespread, and in the 1940s, the US military employed Naugahyde in several areas of the war.

Modern Developments

While some historians claim that the history of counterfeiting leather goes back to the 15th century, these Chinese efforts in the manufacturing of synthetic leather have never achieved a significant level. Only until oil-based polymers were developed at the end of the 19th century did mass production become practical as a substitute for leather. Following the lead of U.S. Rubber, a variety of other entities started making artificial leather products from the 1950s onward. While Naugahyde remained the dominant trademark for synthetic leather in the consumer consciousness until the waning decades of the 20th century, competitors gradually started to supplant this brand's dominance in the artificial leather market.

Environmental Movement Impact

The environmental movement in the 1970s led to a better understanding of the risk of synthetic textiles and a negative change in popular perceptions of counterfeit leather manufacture. In the last couple of decades, some producers have begun to create alternatives to traditional types of false leather that are manufactured from petroleum-based polymers which are not biodegradable and ecologically hazardous. Although these initiatives were generally unsuccessful, in recent years, many firms have been able to produce non-PVC forms of fake leather. So far, however, these types of artificial leather-based vegetables have not been important in the world's fake leather industry.

Manufacturing Process of Fake Leather

Manufacturers can manufacture false leather by using a number of various production techniques. Presstoff is, for example, produced by processing pulp with a particular kind of resin which offers better durability for this plant-based substance. However, it has traditionally prohibited extensive Presstoff manufacture, as this leather substitute is separated under damp circumstances and cannot withstand any considerable bending.

Production Steps

Today, the most fake leather available on the market is a textile basis coated with plastic. Polyurethane (PU) and polyvinyl chloride (PVC) are two plastics most often used in synthetic cube manufacture and the methods used to produce these polymers are relatively different, but they are quite similar to their underlying textiles.

1. Obtaining the Base Material

For their textiles, the majority of fake leather producers utilize cotton or polyester as their foundation materials. Polyester kinds of cotton textiles are generally porous and rough, therefore they need specifically produced. This is the basis for fake leather. In certain circumstances, fake leather producers may also produce their own base materials, although they are far more likely to get the basic ingredients from production facilities from third parties.

2. Formulating the Plastic

Furthermore, fake producers of the leather must shape the plastic materials they bind. For example, the combination of salt and petroleum components is composed of PVC. Chlorine is generated by the manufacturers by subjecting salt to electrolysis and then combined with petroleum-derived ethylene. The method of creating PU is slightly more complex, with the application of isocyanates, polyols, and other additives. In PU manufacturing, the different polymers are reacted and subsequently processed.

3. Binding the Materials

Then false producers of leather bind the underlying fabrics with PU or PVC. Although a number of techniques can be utilized, the plastic coating is usually melted and superimposed in the textile foundation.

4. Cutting and Preparing the Fabric

The plastic is trimmed into the appropriate form and size once it's attached to the underlying tissue. Fake leather is sold in long strips in most cases by the courtyard.

Production Note

The procedure used to create false vegetable leather is slightly different from the preceding stages, but every firm that produces this substance at present has its own way of manufacturing.

Applications and Production Locations

Common Uses

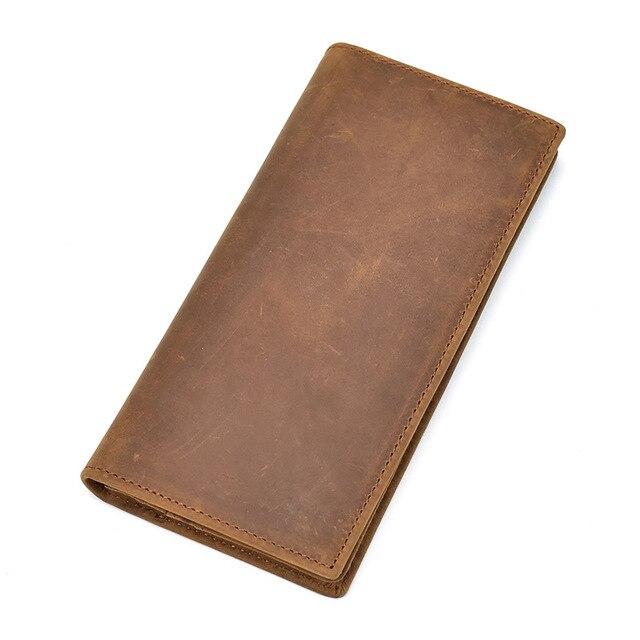

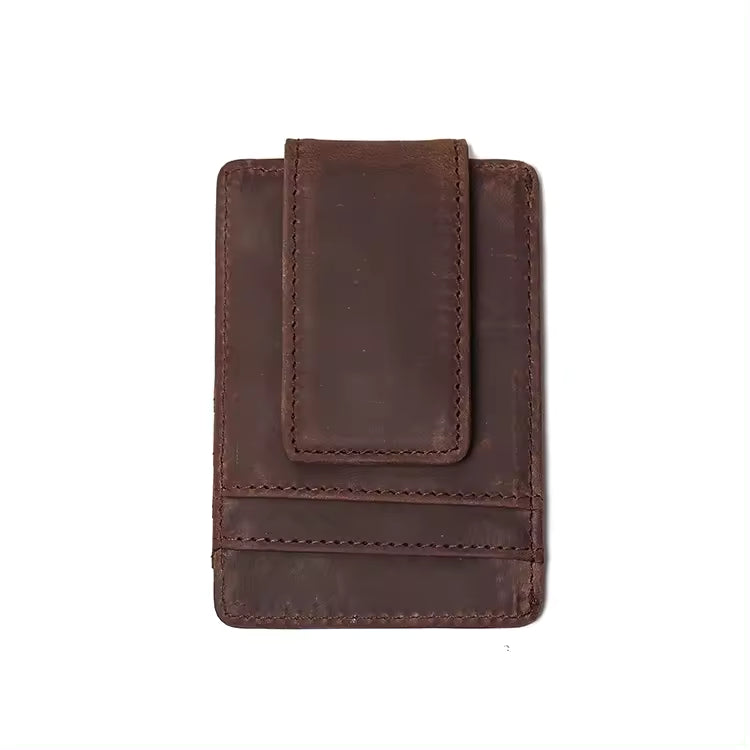

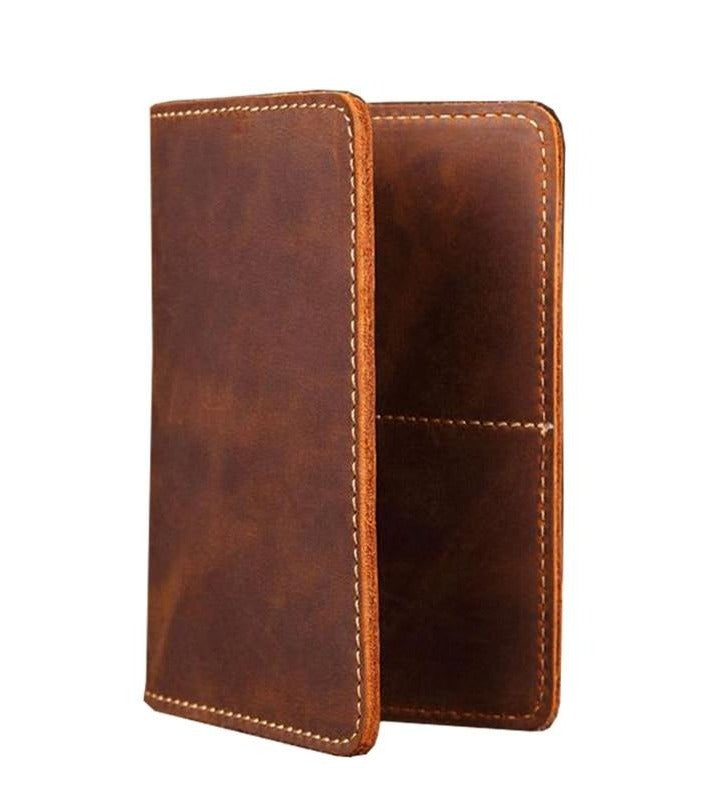

Faux leather, a man-made alternative to genuine leather, serves as an eco-friendly substitute that consequently uses artificial materials instead of animal products. These synthetic materials, particularly polyurethane and polyvinyl chloride (PVC), are petroleum-based alternatives that form the base for many popular items. While synthetic leather is common in mass-produced items, some manufacturers still prioritize genuine leather for premium products. For instance, our experience with The Bard Weekender duffle bag demonstrates why high-quality crazy horse leather remains the preferred choice for luxury travel goods. This premium leather allows for superior durability and develops a unique patina over time, something synthetic alternatives cannot replicate.

Furniture pieces such as sofas, auto seats, chairs, and coffee tables frequently feature flexible, cruelty-free upholstery material and are commonly used in various forms of wall hangings. In the fashion and travel goods industry, while faux leather has become popular for mass-market products, genuine leather continues to dominate the luxury segment. The Bard Weekender exemplifies this trend, featuring high-quality crazy horse leather that provides unparalleled durability and comfort through its ergonomically designed straps and handles - qualities that are difficult to achieve with synthetic materials.

Global Production

China is the biggest fake leather manufacturer. This country also has the biggest market for polyurethane faux leather items and exports them to Asian, European, South American, and North American consumers across the world. The world's need for false leather goods is projected to rise proportionally as more nations achieve world levels of industrialization. In regions where poverty is widespread yet poor climatic conditions cause demand for weather-resistant fabrics continues to push the relatively cheap prices of synthesizing leathers over genuine leather.

Types and Costs of Fake Leather

Cost Considerations

Since synthetic leather is made in the textile form without weaving, it is the price per yard instead of the price per pound that measures the cost of this material. Although the prices of synthetic leather per yard vary according to the fake leather, this kind of cloth typically raises around $10-$25 per yard. While existing varieties of counterfeit leather such as PU and PVC leather typically cost less, it is far more expensive to use new forms such as veggy oil-based leather. Bulk discounts on big quantities of false leather may be available.

Different Types

Every variety of fake leather has distinct characteristics and for a given purpose, each type of this synthetic substance is ideal:

1. PU Leather

This material is the cheapest synthetic leather available on the market. It is, therefore, less durable and pleasant than other fake leather kinds.

2. PVC Leather

PVC fleece is slightly longer lasting than PU fleece and also more widely made. Leather from PVC is sometimes referred to as leather "poromeric."

3. Leatherette

In particular, the word "leatherette" refers to any kind of leather made from plastic material and base. Therefore, the examples of leatherette are both PU and PVC leather.

4. Vegetable Oil Leather

Recent testing of vegetable oil leather was begun by the producers. Vegetable oil leather also looks to be more durable than PU or PVC leather, as well as more ecologically friendly. However, it is also considerably more costly than fabric than any other form of synthetic leather, which has made it a niche commodity for vegans that do not want to harm the environment.

Environmental Impact and Sustainability

The typically negative environmental impact of Faux leather manufacture is significant. While the manufacturing of artificial leather saves harm to animals, the permanent build-up of this non-biodegradable substance in the world's ecosystems hurts animal life ironically. The manufacture of derivatives of the fossil fuel used in counterfeit leather production, such as ethylene, unavoidably introduces poisonous chemicals into the environment, and oil is a resource restricted to drilling, which is harmful to life in plants and animals.

Long-term Environmental Effects

Because synthetic leather cannot be biodegraded, it will stay in the environment once it has been removed. While scientists don't know how long it takes synthetic materials such as PU and PVC to biodegrade, well-known estimations imply that they will stay at least 200-500 years after production in the environment. Since genuine leather biodegrades over a decade or two, counterfeit leather's polluting power is significantly bigger.

Production Location Impact

It also takes into account that China produces the bulk of fake leather. The Communist leadership in the nation is famously lax in terms of human rights norms, but the ability of the labor base to implement effective environmental management sharply deteriorates when people are exploited rather than empowered. Although imitation leather manufacture in the third world is cheaper, it has a bigger impact on the environment.

Comfort and Breathability of Faux vs. Real Leather

| Feature | 🐄 Real Leather | 🧪 Faux Leather |

|---|---|---|

| Breathability | Natural pores → excellent airflow | Improved with micro-perfs |

| Comfort | Molds to body, softens over time | Modern types: flexible, lightweight |

| Warm Weather | Cooler, less sweat | Can trap heat (older types) |

| Best For | Long wear, hot climates | Style, budget, vegan |

PH Climate Tip: Real leather wins in humid heat. Modern faux with perforations = solid alternative.

When comparing the comfort and breathability of faux leather to real leather, it becomes evident that each material has its own unique characteristics. Real leather, made from animal hides, often offers superior breathability, allowing air circulation that keeps the skin comfortable, particularly in warm conditions. This natural material tends to mold and conform to the shape of the body over time, creating a personalized fit that many users find appealing.

On the other hand, synthetic leather, although it can mimic the appearance of genuine leather, often lacks the same level of breathability. However, modern advancements in synthetic materials have improved their comfort significantly. Many faux leathers now incorporate micro-perforations and advanced textile technologies to enhance airflow, making them a viable option for those seeking comfort without sacrificing style. Ultimately, the choice between faux and real leather often comes down to personal preference and the specific use case, as both can provide a degree of comfort depending on the situation.

Comparing Different Leather Types

Full Grain Leather

Real leather may also be referred to as full-grain leather, the finest grade of leather you can get. The top layer of the animal skin hides with inherent flaws is full-grain leather. Because of its thickness, genuine leather is difficult to work with yet is the longest lasting for producers.

Bonded Leather

Bonded leather consists of waste and remaining fibers from the production of real leather, combined with a polyurethane binder. These pieces are then rolled together with glue to attach the fibers to a paperback. To produce a genuine leather texture, a polyurethane coating can be applied and embossed. Most bonded leather includes just genuine leather of 10 to 20 percent.

Key Differences

The differences between these types include:

- Cost variations (real leather being most expensive)

- Durability differences (real leather being most durable)

- Appearance and texture variations

- Sustainability considerations

- Care and cleaning requirements

- Distinct smell characteristics

Why Trust Our Leather Expertise?

At Steel Horse Leather, our deep understanding of both genuine and synthetic leather comes from years of hands-on experience in leather craftsmanship. Our master artisans have dedicated their lives to perfecting their craft, working intimately with various types of leather and developing an expert understanding of leather properties, characteristics, and manufacturing processes. This extensive experience allows us to provide comprehensive insights into both traditional and modern leather alternatives.

Our commitment to leather expertise extends beyond mere craftsmanship. We've invested significant time and resources into thoroughly researching and understanding the entire leather supply chain, from raw material sourcing to final product creation. Our team has personally vetted numerous leather providers, gaining firsthand knowledge of various tanning processes, quality standards, and ethical manufacturing practices. This comprehensive understanding of both traditional leather processing and modern synthetic alternatives positions us uniquely to provide accurate, practical insights into the differences between genuine and fake leather.

As artisans who work with premium leather daily, we've witnessed firsthand how different types of leather - both genuine and synthetic - perform under various conditions. Our expertise isn't just theoretical; it's built on years of practical experience creating durable, high-quality leather products that stand the test of time. This hands-on experience allows us to offer valuable insights into the durability, maintenance, and practical applications of different leather types, helping our readers make informed decisions about their leather purchases.

Frequently Asked Questions

What Is Fake Leather Made From?

Fake leather is typically made from a textile base (usually cotton or polyester) coated with plastic polymers, primarily polyurethane (PU) or polyvinyl chloride (PVC). Some newer versions are made from vegetable-based materials.

How Does Fake Leather Compare to Real Leather in Terms of Durability?

While fake leather is resistant to wear and cutting, it is generally less durable than real leather. Genuine leather can last 10-20 years or more, while synthetic leather's laminated surface typically deteriorates after a few years of use.

Is Fake Leather Environmentally Friendly?

No, traditional fake leather is not environmentally friendly. It's non-biodegradable, taking 200-500 years to break down, and its production involves toxic chemicals. However, newer vegetable-based alternatives are being developed to address these environmental concerns.

How Can You Tell the Difference Between Real and Fake Leather?

The main difference is in the touch and feel. Fake leather has a more plastic-like feel, while real leather has a natural, distinctive texture. Even inexperienced people can generally distinguish between the two through touch.

What Are the Price Differences Between Real and Fake Leather?

Artificial leather and faux leather materials are generally much cheaper alternatives to genuine leather, typically costing between $10-25 per square yard. These synthetic products, including polyurethane (PU) leather and polyvinyl chloride (PVC), represent popular choices for budget-conscious consumers. The manufacturing process of these man-made materials often involves a fabric base with a plastic coating that creates a grain pattern similar to authentic leather.

Conclusion

Although the low price of imitation leather might be appealing, the long-term worth of your buying must be taken into account. Although many counterfeit types of leather are interesting as they are simple to purge with strong chemicals, after only a few years of usage the laminated surface typically crashes. On the other hand, genuine leather was known to survive ten to twenty years or more.

References

Alkali, P., Olatunji, T., & Morakinyo, A. (2023). The economics of planned obsolescence of manufactured goods: a case study of ceramics and leather products. NIU HMS, 8(4), 123-130. https://doi.org/10.58709/niujhu.v8i4.1736

Choi, S., Lee, D., Zo, S., Sood, A., & Han, S. (2025). Gel-based approaches to vegan leather: opportunities and challenges in mimicking leather properties. Gels, 11(6), 395. https://doi.org/10.3390/gels11060395

Eisen, C., Schenten, J., Theis, A., Rehn-Groenendijk, J., Helferich, M., Müller, H., … & Hanss, D. (2024). Toward system innovation for more sustainable chemistry: insights into consumers' perceptions, knowledge, and behavior related to traceability and product design strategies along leather supply chains. Frontiers in Sustainability, 5. https://doi.org/10.3389/frsus.2024.1351638

Rashid, A., Shah, A., Khan, S., Adamjee, M., & Shahab, D. (2024). Potential of cactus leather in pakistan's leather industry: a qualitative analysis. International Journal of Social Science & Entrepreneurship, 4(3), 1-16. https://doi.org/10.58661/ijsse.v4i3.298

Vegan leather from kombucha tea and scoby. (2022). MCET. https://doi.org/10.55162/mcet.03.097