Bonded leather is a combination of leather scraps, leather leftovers, and a bonding agent (typically plastic). It is then pressed into sheets that can be used as is for upholstery or to be made into finished leather goods. The use of bonded leather has been controversial for many years. While it is cheaper, easier to produce, and closer to the look and feel of actual leather, it is not considered real leather by many people. The primary reason for this is that the bonded leather is not an original part of the animal, but rather a manufactured material that can lack durability and often looks different from real leather.

Key Takeaways

- Bonded leather is a cost-effective alternative containing only 10-20% real leather content, making it significantly different from genuine leather products.

- The manufacturing process involves six key steps: shredding, mixing, extrusion, dyeing, stamping, and finishing, resulting in a highly customizable material.

- While initially attractive and affordable, bonded leather typically has a short lifespan of 2-3 years before showing significant wear and tear.

- The material requires different care than genuine leather and cannot be conditioned or repaired effectively once damaged.

- Despite its limitations, bonded leather serves a market need for affordable leather-like products in furniture, accessories, and bookbinding.

What is Bonded Leather?

In Bonded Leather there are remnants of leather, which constitute between 10-20% of its content. The remnants are ground up and coupled with a fibrous or paper backing to form a pulp formulation that is coated with polyurethane. The polyurethane coating adds a protective surface and helps hold the material together. Research published in the Journal of Tekstil Ve Mühendis confirms that bonded leather typically contains approximately 10-20% genuine leather remnants combined with synthetic materials like polyurethane, a composition that helps reduce waste in leather production (Efendioğlu et al., 2025). While this recycling aspect offers some environmental benefits, the sustainability of bonded leather remains debated when compared to emerging plant-based leather alternatives.

A leather called bonded leather is made from leather scraps ground up into a powder. This makes it possible to use lesser pieces of leather, which normally would end up in waste.

Occasionally, old, worn leather is reconstituted into newer materials with the aid of a machine. This kind of leather is called reconstituted leather, or blended leather.

In a way, bonded leather is a mixture of scraps bonded together using polyurethane or latex. The bonded leather mixture can range from 10% to 90%. The percentage of leather used for the mixture influences the aesthetic and functional properties of the product.

To give the impression of natural leather, the surface of the leather is often stamped with a grain pattern. The surfaces are embossed with a variety of colors, sometimes vivid ones, so the color of the finished product can be customized. This makes it a versatile material that's available in a variety of color and texture combinations.

A Brief History of Bonded Leather Furniture

The history of bonded leather furniture dates back to the late 20th century, emerging as a cost-effective alternative in an increasingly price-sensitive market. Initially created to address the problem of leather waste, bonded leather combined leftover scraps with synthetic materials, giving manufacturers the ability to produce leather-like products at a fraction of the cost of genuine leather.

As consumer demand grew in the 1980s and 1990s for more affordable upholstered furniture options, bonded leather rapidly gained popularity for its aesthetic appeal and versatility. It allowed furniture makers to offer a leather-like look that was more accessible to the average consumer, particularly in mass-produced items such as sofas, chairs, and office furnishings. However, the rise of bonded leather was not without controversy as traditional leather aficionados often criticized it for its lack of durability and authenticity. Over the years, despite these criticisms, bonded leather has carved out its niche in the market, particularly appealing to those seeking stylish, budget-friendly options in home décor and office environments. As sustainability concerns continue to influence purchasing decisions, the utilization of recycled leather remnants in bonded leather production has also begun to resonate with environmentally-conscious consumers, enhancing its appeal in an ever-evolving marketplace.

Why Bonded Leather Fell Out of Favor with Furniture Makers & Retailers

As the appeal of bonded leather began to wane, both furniture makers and retailers shifted their focus toward more durable and sustainable alternatives. Initially, bonded leather was highly sought after for its cost-effectiveness and aesthetic resemblance to genuine leather. However, over time, its limitations became increasingly evident. Consumers began to prioritize long-lasting quality and authentic materials, driving the demand for full-grain and top-grain leather products that boast superior durability and character.

Additionally, as environmental awareness surged, the synthetic nature of bonded leather—coupled with its tendency to deteriorate quickly—left eco-conscious buyers yearning for sustainable options. Retailers, recognizing the shift in consumer preferences, began to phase out bonded leather offerings in favor of products that resonate better with their customers' values, ultimately leading to a decline in its popularity in the furniture market.

How is Bonded Leather Made?

In principle, its production is similar to paper as well, though its composition can differ significantly. The leather scrap and fibre is mixed with bonding agents and extruded onto a backing cloth with either a fibrous backing or a paper backing. It can then be treated like leather by dyeing and embossing, even though the color and pattern were inserted into the material only as a surface treatment. Glossiness is achieved with polyurethane treatment. According to research by Efendioğlu and colleagues, the manufacturing process of bonded leather closely resembles paper manufacturing, where shredded leather scraps are mixed with bonding agents and extruded onto backing material before being dyed and embossed to imitate natural leather (Efendioğlu et al., 2025).

1. Shredding

Shredded leather scraps and fibers are ground up from high intensity machines, and from lower grade hides. These can come from the trimmings left from the production of natural leather goods, or discarded in the production of bonded leather products, or just leftover scraps in general.

2. Mixing

When shredded leather is mixed with a polyurethane plastic mixture, the fibers are held together as they are connected by the plastic mixture when it settles and solidifies, giving leather fabrics this "pulp" name from the similar paper processing process.

Some mixes may be dense, strong, firm, soft, or hard, while other may be more supple, dense, firm, strong. Trade secrets are kept about some of these mixtures. Each of these mixtures enhances the overall characteristics of the final leather product.

3. Extrusion

After it has been bonded, the mixture is then extruded onto a flat backing. Extrusion may take place by gravity or by machines that push the mixture evenly out onto the backing.

Typically, the backing is made of a paper or fiber. The backing accompanies the bonded material and helps it adhere and take the final shape.

If needed, the mesh can also be created from a fine fiber, plastic, or metal. This allows for more gripping areas to hold the pulp, and it dries more readily after the pulp has been extruded onto the backing.

In bookbinding, bonded leather might have a paper backing, while in upholstery it might be on a fabric backing.

4. Dyeing/Coloring

Colors can be applied to leather that has dried on the backer after the pulp. This is normally a superficial treatment that does not penetrate very deeply into the material.

Colors penetrate fully into natural leather, but not into synthetic leather. Any colored dye can be applied to the surface of plastic to treat the surface.

5. Stamping/Embossing

When the bonded leather has been colored, it can be given a surface texture to simulate the natural grain of genuine leather. This may also be used to create a design that is visually appealing.

Stamping natural leather is sometimes used to cover blemishes, but stamping bonded leather is designed to finish its surface. Due to the bonding and extrusion process, the bonded leather finish is usually pretty even.

Based on what type of goods it will be used for, different textures could be incorporated into the final product. Due to the fact that this is a mostly synthetic material, bonded leather offers a chance to introduce stylish and functional textures.

6. Finishing

Finishing bonded leather with synthetic surface protectants is usually done after it has been stamped/embossed. This process yields a shiny appearance to the leather.

These finishes are generally polymers that resist water and scratches/abrasions and provide a layer of protection to the material beneath.

Scents can also be applied to the finish to help make the bonded leather smell like natural leather.

Uses and Applications

Upholstered leather furniture is often made from bonded leather as opposed to natural leather since the cost is much less than natural leather. Thus, this means that furniture stores offer bonded leather at a relatively low price as a means to own real leather.

Common Applications

Various types of bonded leather are also used on books as covers due to their durability and the fact that they can be shaped into any shape. They can also be made in any color, which makes them perfect for varied applications.

The linings, for example, or externally facing surfaces of clothes, jackets, pants, skirts, and hats, could be made of this type of leather. Shoes and boot pieces might also have this type of leather.

This type of leather is commonly used in laptop, camera, and media storage cases, media storage bags, and diploma covers. It can also be found in backpacks, laptop cases, and makeup bags for travel use.

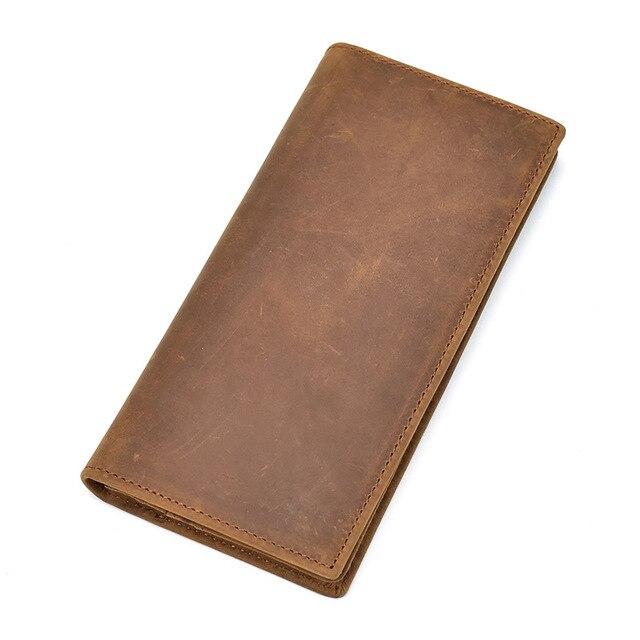

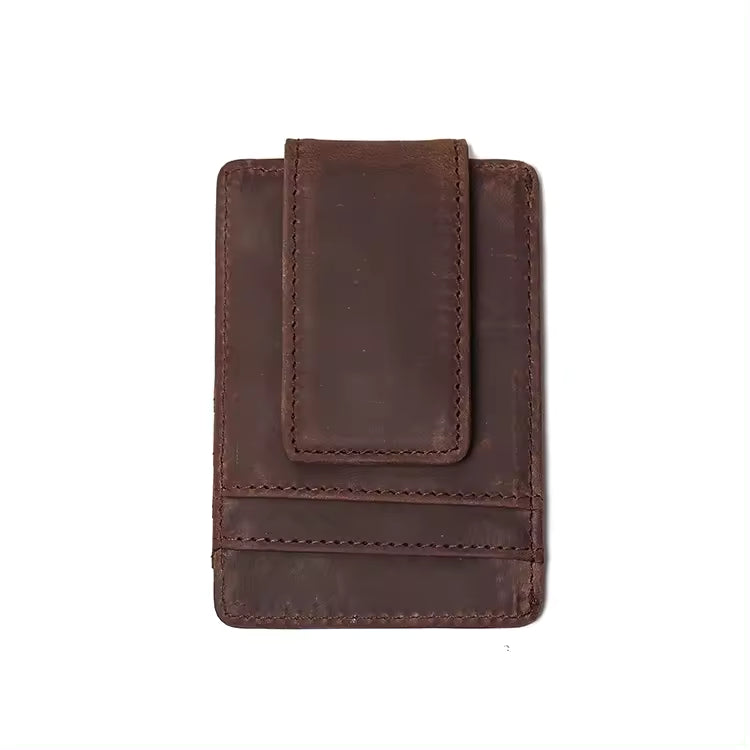

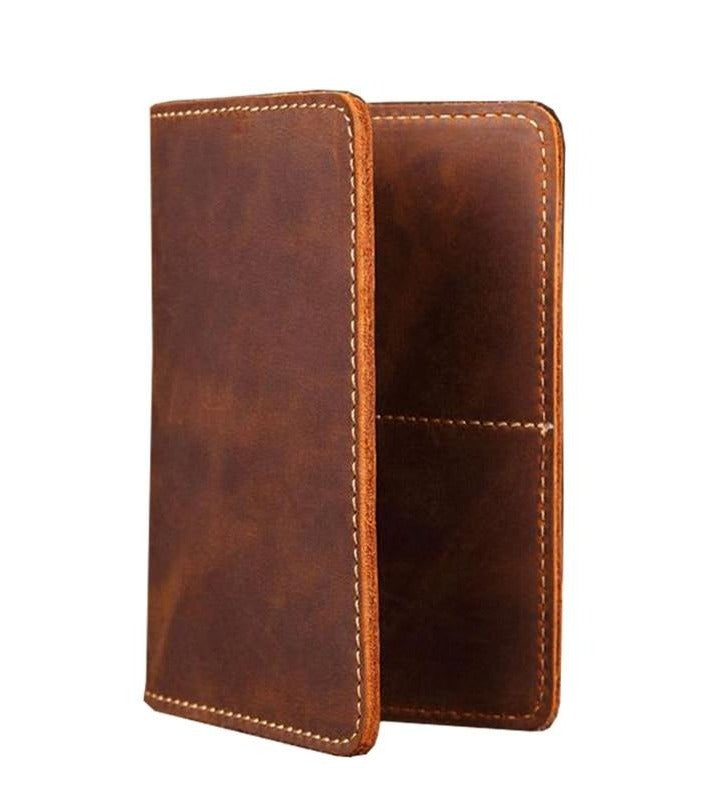

Bonded leather is used for making belts, straps, wallets, key chains, eyeglass cases, sunglasses, jewelry boxes, key rings, credit card cases and more.

During our development of the Eira Duffle Bag, we specifically chose not to use bonded leather, opting instead for premium crazyhorse leather. This decision was based on extensive material testing that showed how bonded leather bags often failed to maintain their structure and appearance over time, particularly in high-stress areas like handles and bottom corners. Our experience demonstrated that while bonded leather might offer initial cost savings, it wouldn't provide the durability and aging characteristics we desired for a premium travel bag designed to last for years.

Durability and Maintenance

Bonded Leather Durability

The fibers in bonded leather are not as accessible to conditioning and treatment as those in natural leather. Over time, the surface of the binding wears, the plastic deteriorates, and the material cracks.

Since bonded leather is polymer-based rather than natural leather, it is able to protect itself against abrasions and moisture. However, once it starts to wear out, it becomes difficult to repair, usually within about 2-3 years. Studies examining leather durability have noted that bonded leather's synthetic backing contributes significantly to its tendency to peel and crack over time, particularly in high-stress applications like furniture upholstery (Abdulhusein & Kadim, 2024). This limited durability remains a primary concern for consumers seeking long-term value in their purchases.

Bonded Leather Peeling

The plastic-based nature of bonded leather means that it will need to be used more carefully than natural leather. Due to the fact that the natural fibers are not exposed, this type of leather cannot be treated or cared for the same way that natural leather can.

The bond leather begins to separate from its backing when it's frequently flexed, as a result of sitting and moving around furniture. After a certain period, it starts to flake and peel away.

When upholstery pieces come off in this way, they are no longer uniformly colored, and the underlying layers of the fabric become exposed. This results in an unappealing piece.

Comparison with Other Leather Types

Bonded Leather vs Genuine Leather

Any layer of the hide can be used to make genuine leather, and the surface is corrected to make it appear uniform. A final surface appearance can be achieved by sanding or buffing the wood to remove defects, spray painting or stamping it to dress up its surface. Leather obtained through this process has characteristics that make it undesirable to use for luxury goods, such as belts and shoes. Genuine leather is still made of natural hide, so it will last longer and perform better than bonded leather.

Bonded Leather vs Full Grain Leather

Generally, only the hair on full grain leather is removed. This cut makes use of the outer layout of the hide, sometimes known as the "grain". Generally, the grain consists of a bunch of leather fiber that are densely packed and fine; this enables the grains to achieve very strong, durable, and durable surfaces. The surface fibers make it more durable than any other leather type, making it excellent for saddles, shoes, and furniture.

Bonded Leather vs Faux Leather

The faux leather material is made of polyurethane or vinyl, and is designed to look like real leather. Faux leather is much less costly than authentic leather. As opposed to genuine leather, it is extremely durable, inexpensive, and easy to clean. Unlike bonded leather which tends to flake and crack over time, faux leather stays a consistent consistency of the material.

Care and Maintenance

How to Clean Bonded Leather

Due to how it is finished, bonded leather can be cleaned gently by wetting the cloth gently. Try to avoid using lint and loose fibers, since this could transfer to the leather's surface. A microfiber cloth could work well here. Make sure that the cloth is not going to transfer any color to any material surface by testing in a small area first or on a separate bonded leather piece.

How to Condition Bonded Leather

Due to its protective finish, bonded leather does not require conditioning. And it doesn't even need to. The surface finish protects the leather underneath. It also acts as a barrier that conditioners cannot penetrate. Cleaning bonded leather products is easy thanks to the protective surface that makes them easy to maintain.

Why Trust Our Leather Expertise?

At Steel Horse Leather, our deep understanding of leather materials and manufacturing processes comes from years of hands-on experience in crafting premium leather goods. Our master artisans have dedicated their lives to perfecting their craft, giving us unique insights into the various types of leather and their properties. This expertise has been particularly valuable in helping our customers understand the differences between genuine leather products and alternatives like bonded leather.

Through our extensive work with different leather materials and our commitment to transparency, we've developed comprehensive knowledge of leather processing and manufacturing techniques. Our experience in sourcing and evaluating leather quality has involved thorough assessments of various leather types, including bonded leather. This practical experience, combined with our direct relationships with tanneries and leather suppliers, allows us to provide accurate, firsthand information about leather quality, durability, and maintenance. When we discuss the limitations of bonded leather or compare it with full-grain leather, we're drawing from real-world observations and material testing in our own workshop, not just theoretical knowledge.

Frequently Asked Questions

How Long Can I Expect Bonded Leather Furniture to Last?

As a man-made material and popular choice for furniture upholstery, bonded leather furniture (also known as composite leather or Reconstituted Leather) typically begins to show signs of wear within 2-3 years of regular use. Unlike genuine leather furniture, which often develops a beautiful patina over time, bonded leather tends to deteriorate, crack, and leather peel, particularly in areas that experience frequent flexing or movement. The quality of material is especially affected by exposure to heat and hot weather.

Can Damaged Bonded Leather Be Repaired?

Unlike full-grain or top-grain leather, bonded leather is extremely difficult to repair once damaged. While leather repair kits and leather repair solutions exist, due to its synthetic nature and production process, when it begins to peel or crack, the damage is usually permanent and will continue to worsen over time. The biggest difference between this and natural leather is in its durability and repair options.

Is Bonded Leather Environmentally Friendly?

While bonded leather does utilize recycled leather scraps and waste leather that would otherwise go to waste, the addition of polyurethane resin and other bonding materials makes it less environmentally friendly than natural leather. The production process involves harsh chemicals and strips of polyurethane, resulting in a larger environmental footprint. Additionally, its shorter lifespan means it needs to be replaced more frequently than quality leather furniture.

Why Does Bonded Leather Feel Different From Real Leather?

The difference in quality comes from its composition and bonding process. Since bonded leather contains only 10-20% leather particles mixed with fiber cloth and organic materials, topped with a layer of polyurethane, it lacks the natural qualities and consistent appearance of genuine leather. This composite material is made from shredded leather fibers and offers a wide variety of color options, but cannot match the premium quality of a single piece of animal hide.

Should I Use Leather Conditioner on Bonded Leather?

No, leather conditioner should not be used on bonded leather. The protective polyurethane coating prevents any conditioning products from penetrating the material, making traditional leather care products ineffective and potentially harmful to the surface.

Conclusion

Overall, bonded leather is a very inferior product in comparison to other leather. It is however cheap which is probably the reason why many consider purchasing it. There is however no harm in purchasing bonded leather. Likewise, it is important to learn the pros and cons before buying. In instances where you do own bonded leather, it is equally important to know how to properly use and take care of it. It might be inferior but with proper care, you can still make the most of it.

References

Abdulhusein, H., & Kadim, B. (2024). Antimicrobial substances and strategies to avoid bacterial and fungal effects in leather manufacturing. Kafkas Üniversitesi Fen Bilimleri Enstitüsü Dergisi, 17(2), 81-91. https://doi.org/10.58688/kujs.1467530

Efendioğlu, N., Yorgancıoğlu, A., Önem, E., & Karavana, H. (2025). Evaluation of the effects of artificial aging on the upper leather of military combat boots. Tekstil Ve Mühendis, 32(138), 146-152. https://doi.org/10.7216/teksmuh.1633953