Leather products are found in all parts of the world. For some, owning leather products is regarded as a status symbol— the more exotic the animal hide used, the more expensive it is. However, most people do think of quality when they think of leather. It makes you wonder what exactly makes it so expensive? How is it made?

Key Takeaways

- leather production is a significant global industry, with China producing approximately 4 billion square feet annually, followed by Brazil and Italy

- The leather-making process remains largely unchanged over millennia, though modern technology has improved efficiency and quality

- full grain Leather represents the highest quality leather available, particularly in crazy horse leather products

- While synthetic alternatives exist, traditional leather remains more environmentally sustainable due to its longevity and natural production process

- The leather industry supports millions of jobs worldwide and primarily utilizes by-products from the meat and dairy industries

Understanding Leather Sources

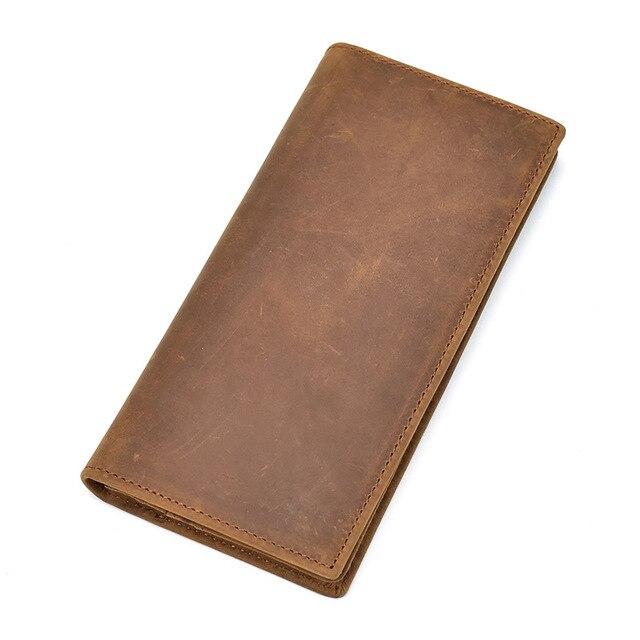

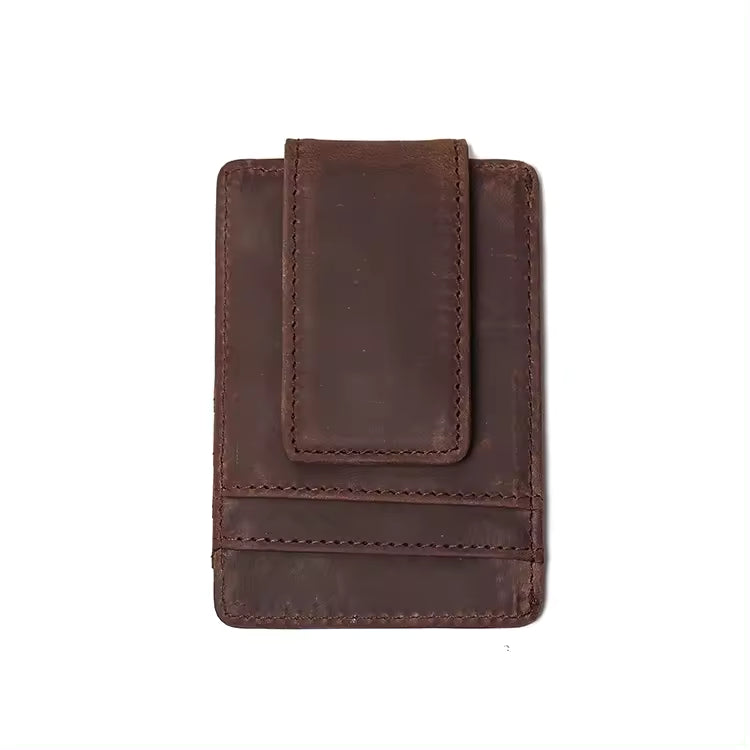

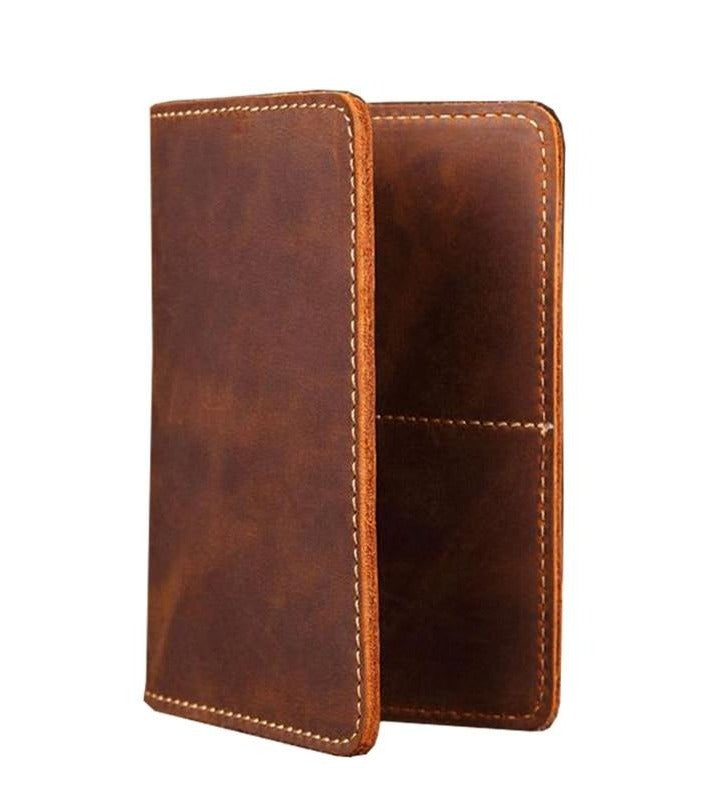

Leather is the final product of tanning rawhide of an animal to make it flexible, yet durable for various uses. Leather is commonly made from cattle skins. The best quality you can get is called Full Grain Leather, we use this in our Crazy Horse Leather. It may also be made from skins of other animals including exotic ones such as kangaroos, pythons, crocodiles, stingrays, and many more.

Global Production

In this day and age, leather production is a huge industry with many industrial hubs worldwide. Not only does the industry boost a country's economy, but also provides jobs for millions of people around the world. According to the Food and Agriculture Organization of the United Nations, China is undoubtedly the highest producer of leather. In fact, China's leather industry produces nearly a whopping 4 billion square feet of leather annually— that's approximately 72 million adult cows! Brazil is next in the list with a production of 1.7 billion square feet of leather annually, followed by (3rd), Russia (4th), and India (5th). For your reference, USA ranks 8th in the list, which produces approximately 6.7 million square feet annually.

Historical Background

Leather is easily one of the most useful and one of the earliest discoveries of man. Historical tests confirm that the use of such material could be traced from 2,000,000 years ago. Leather was used by our ancestors as a protective covering against elements such as heat, cold, rain, and other hazards present in the environment. Our ancestors hunted wild animals for food, then subsequently made use of the animal hide as footwear, clothing, and even shelter. Similarly, at present, hides used to make leather are a by-product of the meat and dairy industries. This is because animals are primarily raised for their meat, wool, and not for their hide. There have been alternatives to leather, such as PU Leather or vegan leather that have been touted as an eco-friendly alternative. However, many times these alternatives can have a much harsher effect on the environment due to the chemicals used and also they tend to not last very long.

Ancient Civilizations and Leather

Archaeologists were also able to discover artifacts and wall paintings in Egyptian tombs dating back to 5,000 B.C. which illustrates the different uses of leather such as footwear, gloves, bottles, cerements for wrapping and burying the dead, as well as military equipment. Around 500 B.C the ancient Greeks even developed tanning formulas utilizing tree barks and plants soaked in water to be used for the preservation of leather— this gave birth to the production of vegetable tanned leather which is still widely produced during modern times. In fact, this is the process we use. Recent archaeological evidence further confirms the sophistication of ancient leather-making practices. Historical records indicate that various tanning methods were utilized in ancient Egypt to create durable leather products, with these techniques being refined over millennia (Elnaggar et al., 2016). The transition from these traditional vegetable tanning methods to modern techniques such as chrome tanning was pivotal in the evolution of the leather industry, allowing for more rapid production at lower costs while fundamentally changing the properties of the final products (Shaer et al., 2023).

Medieval and Modern Development

During the middle ages, leather became the preferred choice of covering of coaches, upholstery of chairs, saddles, and bookbinding. Due to its durability, leather has been the ideal material as cover because it was easy to maintain and does not easily absorb foul odor.

Modern technology has allowed further advancement in the leather industry. More efficient and cost-effective methods have been discovered to produce leather without compromising good quality. Technology has paved the way for the development of chemical formulas and state of the art processing methods to improve the durability and aesthetics of leather.

Evolution of Leather-making Technology

| Era | Technology | Impact |

|---|---|---|

| Ancient Pre-1800s | Brain tanning, smoke, vegetable pits (oak, chestnut) | 30–365 days per hide · 100 % manual · beautiful but slow |

| 1858 Chrome Tanning Invented | Chromium(III) salts | Cuts tanning from months → 1–2 days · softer leather · cheaper mass production |

| 1920–1960 Mechanical Revolution | Drum tanning machines, hydraulic presses, splitting machines | One tannery now does the work of hundreds of men · top-grain becomes mainstream |

| 1990–2010 Automation Era | Computer-controlled dosing, automated sammying & setting machines | Consistent thickness, color, softness · 90 % reduction in human error |

| 2015–2023 Sustainability Wave | Metal-free tanning, bio-based agents, water recycling (95 % reuse), LWG certification | Luxury brands switch to “green” leather without losing quality |

| 2024–2025 Cutting Edge | AI-controlled tanning drums, blockchain traceability, lab-grown collagen + plant hybrids, 3D leather printing (prototypes) | Zero-waste pilot plants · full-grain from raw hide to finished leather in < 7 days while keeping full-grain patina |

| 2025 Reality Check What the Best Tanneries Use Today | ||

|---|---|---|

| Still vegetable-tanned full-grain? | Yes – 6–10 weeks in oak/quebracho pits | Patina king |

| Eco chrome-free alternatives? | Wet-white + synthetic tannins | 70 % less water & chemicals |

| Automation level | Robotic spraying, laser measuring, AI color matching | ±0.1 mm thickness tolerance |

| Traceability | Blockchain from farm → finished bag | Luxury buyers demand it |

2025 Golden Truth (worldwide):

The best leather today is still made the old way (slow vegetable tanning + full-grain) — but with new tools that make it make cleaner, traceable, and perfectly consistent.

Tradition + technology = the unbeatable 2025 sweet spot.

The evolution of leather-making technology has played a pivotal role in shaping the industry as we know it today. Historically, leather production relied heavily on traditional methods, which, while effective, were often labor-intensive and time-consuming. However, the advent of modern technology has revolutionized this age-old craft, introducing advanced techniques that enhance efficiency without compromising quality. Innovations such as computer-controlled tanning machines and automated drying processes reduce processing time and improve consistency in the final product. Moreover, sustainable practices have become increasingly important, leading to the development of eco-friendly tanning agents and more energy-efficient machinery.

This modernization not only helps in meeting the growing global demand for leather goods but also emphasizes a responsible approach to production, ensuring that leather remains a prized material for generations to come. By merging traditional craftsmanship with cutting-edge technology, contemporary leather-making not only preserves the essence of its rich history but also positions itself favorably in a rapidly evolving market.

Impact of Leather on Fashion and Style Trends

Leather has long been celebrated not just for its functionality but also for its undeniable impact on fashion and style trends throughout history. From classic leather jackets that became symbols of rebellion and individuality to elegant leather handbags that exemplify luxury and sophistication, this material has transcended generations and remains a cornerstone in the fashion world. Designers continuously draw inspiration from leather's versatility, utilizing it in various forms—be it in ready-to-wear collections, haute couture, or accessories. This adaptability allows it to fit seamlessly within different styles, from edgy streetwear to refined high fashion.

Additionally, leather's ability to age beautifully, developing a unique patina over time, adds to its allure, making each piece a personal statement. With sustainability becoming increasingly important in today's fashion landscape, leather's natural durability positions it as not only a timeless choice but also a conscious one. As trends evolve, leather continues to assert itself as a staple, shaping and reshaping our perceptions of style and individuality.

The Leather-Making Process

Have you ever wondered how leather is transformed or where does leather come from to be turned into your favorite bags, shoes, clothing, upholstery cover, and other things? It first goes through a very lengthy and meticulous process before it reaches to shops and finally to your hands. The process of making leather has not changed much over the years, but the presence of modern technology has indeed helped the industry produce such quality material at a more efficient means. The steps below are the key stages of production:

Initial Processing

Curing. Although hides of any other animal are also used to make, cattle hide is the most common material used as it is the most abundant material available. Rawhide, the material used for leather, is a by-product of the meat and dairy industry from various parts of the world. After procuring the rawhide, it is immediately treated with salt to avoid bacteria formation and prevent it from decomposing.

Preparation Stages

Soaking. Once the hides are cured and brought to the tannery, they are soaked in water for several hours to remove the salt and dirt. At the same time, this is to also reabsorb the moisture lost from curing.

Liming. The hides are then soaked in lime in the process called liming where unwanted hairs and proteins are chemically dissolved and opens up the fiber structure. This swells the material considerably.

Fleshing. Some flesh may still be present in the hide, hence they are removed in this stage. The material is placed in a machine with huge blades and a revolving cylinder in order to remove the remaining flesh. At the same time, this process regularizes the thickness of the material and flattening it.

Material Processing

Trimming. During this stage, useless materials are cut off from the rawhide to give them a better shape.

Splitting. After the material is trimmed, it is then cut horizontally to separate the external layer and the lower layer called the top-grain and split-grain respectively.

Final Stages

Tanning. This stage is the most crucial and most important. In this stage the hides are placed in a large drum filled with tanning agents that are responsible for transforming protein from the hide into a durable and flexible material, allowing the material to be more resistant to endure repeated cycles of wetting and drying. After this, the hide is transferred into a machine that squeezes excess moisture. Afterwhich, the material is sorted according to their grade and destination depending on its use.

Re-tanning. The hide undergoes another tanning process to fully prepare for its intended use.

Dyeing. Tanners then apply dye to the material to further enhance the material's natural beauty! A variety of shades are produced to suit trends in fashion. However, this step could also be skipped if desired. Subsequently, the leather is stretched and oils are also applied to seep into the material, making it more flexible and lubricated.

Finishing. This is the last step of the process of leather making. During this stage, the final set of chemicals are applied to create a protective surface over the material. A final grading or quality check of the material is then conducted before dispatch to customers!

Practical Application in Modern Products

The intricate leather-making process we've described directly influences the quality of modern leather goods. For instance, our Bjarke Weekender bag exemplifies how high-quality crazy horse leather, when properly processed through these stages, develops unique characteristics. During development of this weekender bag, we observed how the careful selection of full-grain leather and proper tanning resulted in a material that not only maintains its structural integrity for a 23.6" x 11.8" x 11.8" design but also develops a distinctive patina over time. The bag's leather handles, which undergo additional processing for softness while maintaining durability, demonstrate how modern leather crafting combines traditional techniques with contemporary needs.

Why Trust Our Leather Craftsmanship Expertise?

At Steel Horse Leather, our deep understanding of leather craftsmanship comes from years of dedicated experience working with this timeless material. Our master artisans have spent decades perfecting their craft, combining traditional leather-making methods with an unwavering commitment to quality. This expertise allows us to not only create exceptional leather products but also share valuable insights about leather production and quality assessment with our customers.

Our commitment to leather excellence extends beyond mere craftsmanship. We've invested considerable time and resources into understanding the complete leather supply chain, from raw hide sourcing to final product creation. Through extensive research and partnerships with ethical suppliers, we've developed comprehensive knowledge of various tanning processes, leather grades, and quality indicators. Our particular expertise in Full Grain Leather and traditional vegetable tanningmethods - the same processes discussed in this article - comes from hands-on experience working with these materials daily.

What sets our expertise apart is our holistic approach to leather production and sourcing. We've personally vetted numerous leather providers, studied various tanning techniques, and maintained strict quality control standards throughout our manufacturing process. This practical experience, combined with our dedication to traditional craftsmanship, enables us to provide not just superior products but also accurate, detailed information about leather production and quality assessment. When we discuss leather-making processes and characteristics, we're sharing knowledge gained from real-world application and years of hands-on experience in the field.

Frequently Asked Questions

How Does Leather Production Impact The Environment?

The leather industry and leather production actually helps reduce waste by utilizing by-products from meat production and the meat industry. While synthetic materials and vegan leather are often marketed as eco-friendly alternatives to leather, these synthetic leather options can have a larger environmental footprint due to chemical processing, fossil fuels usage, and shorter lifespan. The environmental impact of traditional leather as a natural product is often subject to common misconception, especially regarding water usage and environmental regulations. The leather industry and leather production actually helps reduce waste by utilizing by-products from meat production and the meat industry. While synthetic materials and vegan leather are often marketed as eco-friendly alternatives to leather, these synthetic leather options can have a larger environmental footprint due to chemical processing, fossil fuels usage, and shorter lifespan. Recent innovations in synthetic leather technology are now focused on enhancing performance while minimizing chemical hazards, including the use of biodegradable materials that present fewer environmental risks (Xiao et al., 2023). Additionally, emerging plant-based alternatives such as leather made from coffee pulp and kombucha have shown potential, though their long-term durability and environmental impacts can vary significantly depending on production processes (Mutuku et al., 2022; Choi et al., 2025).

What Makes Some Leather More Expensive Than Others?

The price of leather products varies based on the type of animal skin used (exotic animals and wild animals command higher prices for exotic leathers), the leather grading (full-grain leather being the highest), and the tanning process used. Various tanning methods, including chrome tanning and vegetable tanning with vegetable-based tanning agents, affect the final quality of the finished product. The extensive leather-making process and quality control in leather craftsmanship also contribute to cost differences, particularly for high-quality leather and Italian leather products.

How Can I Determine Genuine Leather Quality?

Look for terms like "full-grain leather" or "top-grain leather," which indicates the highest quality. Genuine leather should have a natural grain with natural imperfections and a distinctive leather smell. The grain pattern on this durable material should be irregular rather than perfectly uniform. When comparing real leather furniture to faux leather or synthetic alternatives, examine the natural grain and surface texture.

How Long Does The Leather-Making Process Take?

The complete process from raw hide to finished leather involves multiple stages including curing, soaking, liming, and various tanning methods. The actual process of transforming animal hide into leather requires careful attention to achieve the desired water resistance and abrasion resistant properties. While technological advancements have improved efficiency in leather production, the entire tanning process can still take several weeks to ensure quality in the finished leather.

What's The Best Way To Maintain Leather Products?

Proper maintenance of leather goods involves regular cleaning with leather cleaner, applying leather conditioner, and protecting from extreme temperatures and direct sunlight. Different types of leather may require specific leather care products based on their tanning process and finish. The wide range of leather products available, from leather furniture to leather jackets, means that understanding proper leather care is essential for maintaining this remarkable material's longevity.

Conclusion

.....and voila! This is where leather comes from. After a lengthy and meticulous process, leather is transformed into your shoes, bags, clothing, and more! Knowing the entire process of making it, makes you appreciate your leather accessories more. The time and effort put into every piece bag before it reaches your hands, makes it more valuable and worth it to purchase.

References

Choi, S., Lee, D., Zo, S., Sood, A., & Han, S. (2025). Gel-based approaches to vegan leather: opportunities and challenges in mimicking leather properties. Gels, 11(6), 395. https://doi.org/10.3390/gels11060395

Elnaggar, A., Leona, M., Nevin, A., & Heywood, A. (2016). The characterization of vegetable tannins and colouring agents in ancient Egyptian leather from the collection of the Metropolitan Museum of Art. Archaeometry, 59(1), 133-147. https://doi.org/10.1111/arcm.12239

Mutuku, M., Ombui, J., & Onyuka, A. (2022). Assessment of coffee pulp as a potential source of tannins for leather processing. Textile & Leather Review, 5, 132-146. https://doi.org/10.31881/tlr.2021.31

Shaer, M., Abd-Elraheem, M., Alfawal, G., Abd-Elhamed, W., Ghaly, M., & Nasr, A. (2023). Possible application of using modified black liquor from rice straw in leather tanning. Journal of Ecological Engineering, 24(11), 197-206. https://doi.org/10.12911/22998993/171403

Xiao, Y., Zhou, J., Wang, C., Zhang, J., Radnaeva, V., & Lin, W. (2023). Sustainable metal-free leather manufacture via synergistic effects of triazine derivative and vegetable tannins. Collagen and Leather, 5(1). https://doi.org/10.1186/s42825-022-00108-0