When it comes to making leather, it takes at least a year for a cow to mature large enough to create a skin large enough for a large panel rather than small pieces sewn together. Not only will this take time, but you will still need to feed and water the animal as well as keep it safe and healthy. This is one of the reasons why leather is so expensive. There is only so much leather that can be extracted from a single animal, and it takes a slew of chemicals to properly cure and treat the leather so that it is nice and usable.

Furthermore, leather is very heavy and difficult to deal with. Making something out of leather necessitates the use of specialized equipment and experience. If any errors are made during the manufacturing process, you must restart from the beginning.

Key Takeaways

- The production timeline for quality leather is extensive, requiring at least a year for cattle to mature sufficiently

- Different grades of leather significantly impact pricing, with full grain being the most premium and bonded leather being the most economical

- The type of animal hide used affects cost, with cowhide being more expensive than alternatives like goat and buffalo

- Color processing, especially for white leather, can substantially influence the final price

- Bulk production in single colors is more cost-effective than small batches of varied colors

Quality and Material Types

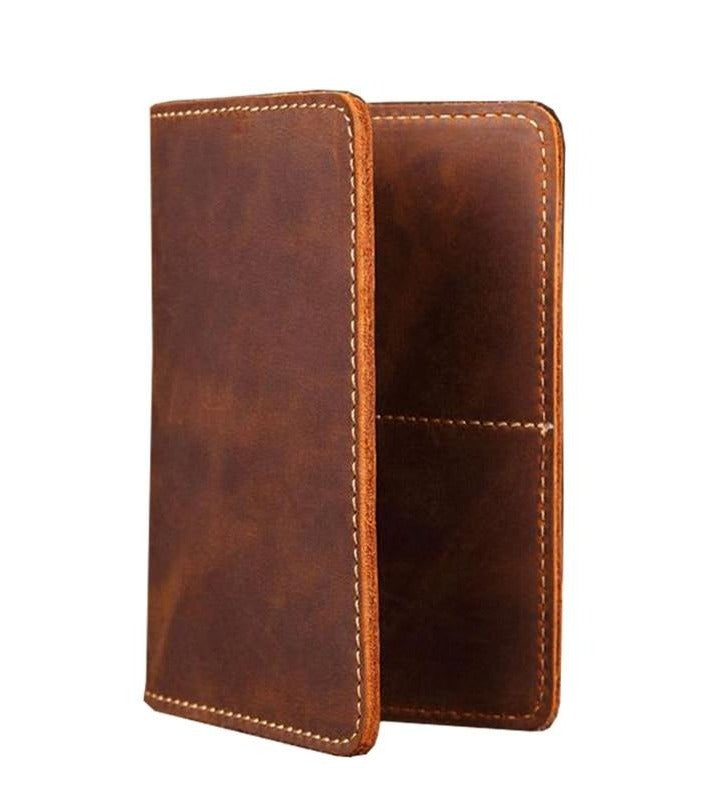

The price of leather goods is usually dictated by the type of leather used and how the product was manufactured. full grain leather is often regarded as the best quality leather, while bonded leather and natural leather are regarded as the lowest quality. Cheaper leather furniture, such as sofas made of bonded leather, is more likely to be found, whereas high street luxury shops usually stock real leather in order to provide more affordable prices. Designer brands, on the other hand, would usually use full grain leather, calf leather, or even exotic leathers such as ostrich. Another factor influencing price is the type of animal skin used. Cowhide is the most common type of leather, so it is more expensive than less expensive alternatives such as goat and buffalo.

Coloring and Treatment Process

It's not surprising that fully dyed leathers are more costly than semi-dyed leathers because it's more difficult and time-consuming to find better-quality hides that can be dyed. Some leathers are finished by machine spraying, which is much less expensive than hand antiqued leathers. It also depends on the color you're making. For example, it is much less expensive to manufacture a large number of hides in a single color rather than a few hides in a variety of less common colors. The money saved by making them in bulk makes the product less expensive for the customer. Because white leather is the most difficult color leather to manufacture, you would expect a white leather jacket or bag to command a higher price.

Our experience with the Bjarke Weekender's development taught us valuable lessons about color processing. While developing the two distinct brown shades for this collection, we discovered that maintaining consistency across large batches of crazy horse leather required precise control of the dying process. This hands-on experience reinforced our understanding of why specialized colors, particularly white leather, command premium prices in the market.

Leather Manufacturing Process

| Stage | What Happens | Time | Result for Premium Leather |

|---|---|---|---|

| 1 Raw Hide Selection | Only top 5–10 % of hides chosen (minimal scars, even grain) | — | Full-grain possible only from Grade-A hides |

| 2 Curing & Soaking | Salt & refrigerate → rehydrate in water + bactericides | 1–3 days | Prevents decay, cleans hair & flesh |

| 3 Liming & Fleshing | Chemical bath removes hair & fat | 1–2 days | Clean, swollen hide ready for tanning |

| 4 Splitting (optional) | Hide split horizontally Top layer = grain side Bottom = split leather |

— | Full-grain keeps entire top layer Top-grain uses sanded here |

| 5 Tanning | • Vegetable tanning (tree bark, 30–60 days) • Chrome tanning (chromium salts, 1–2 days) |

1–60 days | Veg-tan = richest patina, eco-friendly Chrome = softer, faster, cheaper |

| 6 Crusting | Re-tanning, dyeing, fatliquoring (oils for softness) | 3–10 days | Color locked in, leather becomes supple |

| 7 Finishing | • Full-grain: light oil/wax only • Top-grain: sanding + pigment coating + embossing |

2–7 days | Full-grain keeps natural marks Top-grain gets “perfect” plastic look |

| 8 Quality Control & Sorting | Hand inspection, thickness check, flex test | 1–2 days | Only flawless pieces become luxury bags |

| 2025 Quick Comparison | ||

|---|---|---|

| Vegetable-Tanned Full-Grain | Chrome-Tanned Top-Grain | |

| Time | 6–12 weeks | 1–3 weeks |

| Patina | Stunning (gets better forever) | None (coating wears off) |

| Cost | 2–4× higher | Budget-friendly |

| Feel | Firm → buttery over time | Soft from day one |

| Durability | Heirloom (20–100 years) | 5–15 years |

Golden Rule 2025 (worldwide):

If it wasn’t vegetable-tanned full-grain and took less than 6 weeks from hide to finished leather, it’s not the real luxury stuff.

| Step | Description |

|---|---|

| Hide Selection | Carefully chosen hides from animals, mostly cattle, serve as the base material. |

| Curing | Hides are preserved through curing to maintain quality and prevent decay. |

| Tanning | Tanning transforms hides into leather using methods like vegetable or chrome tanning. |

| Dyeing and Treatments | Hides are dyed and treated with processes like embossing or protective coatings. |

| Quality Control | Strict quality checks ensure the final leather meets high standards. |

The leather manufacturing process is intricate and multifaceted, beginning with the careful selection of hides from various animals, predominantly cattle. Once the hides are sourced, they undergo a rigorous curing process to preserve their quality and prevent decay. This typically involves tanning, which can be executed through several methods, such as vegetable tanning or chrome tanning, each affecting the leather's final characteristics.

After tanning, the hides are dyed and may undergo additional treatments to enhance their appearance and functionality. This can include processes like embossing or applying protective coatings. The entire journey from raw hide to finished leather product demands skilled craftsmanship and specialized equipment, contributing to the overall cost. Each phase, including the essential quality control measures, adds to the time and resources required, underscoring why high-quality leather is often perceived as a luxury material.

Why Trust Our Leather Expertise?

At Steel Horse Leather, our deep understanding of leather craftsmanship comes from years of hands-on experience in selecting, processing, and crafting premium leather goods. Our master artisans have dedicated their lives to perfecting traditional leather-working techniques, bringing decades of collective expertise to every aspect of leather production discussed in this article. This intimate knowledge of leather crafting allows us to provide authoritative insights into why quality leather commands premium prices.

Our commitment to leather excellence extends beyond mere craftsmanship. We've invested considerable resources in developing comprehensive knowledge of the entire leather supply chain, from raw material sourcing to final production. Through our extensive vetting process of leather suppliers and tanneries, we've gained firsthand experience with various grades of leather, tanning methods, and coloring processes. This hands-on involvement in every stage of leather production has given us unique insights into the factors that influence leather quality and pricing.

What sets our expertise apart is our holistic approach to leather craftsmanship. While many focus solely on the end product, we understand the entire journey from animal husbandry to final finishing touches. Our master artisans work exclusively with premium materials, giving us practical experience with everything from full-grain leather to specialized dying techniques. This comprehensive knowledge enables us to explain not just the what, but the why behind leather pricing and quality assessment, helping our readers make more informed decisions about their leather purchases.

Frequently Asked Questions

How Can I Determine if I'm Getting Quality Leather?

When shopping for genuine leather products, look for terms like "full grain leather" or "grain leather" on the label, and be wary of terms like "bonded leather" or "synthetic leather." High-quality leather should have a natural grain with natural imperfections and a distinctive smell. The type of leather used and the tanning process, whether traditional methods like vegetable tanning or modern chrome tanning methods, can significantly impact leather quality. Premium leather and exotic leather types from animal hides such as crocodile leather, ostrich skin leather, or calf leather often showcase superior materials and meticulous craftsmanship.

Why Is White Leather More Expensive?

A white leather jacket or other white leather products command a higher price because they're among the most expensive type of finished leather to manufacture. The production process requires more intensive leather processing, specialized equipment, and higher-quality raw material. Additional costs come from the skilled labor needed and the careful manufacturing process to maintain the material quality while achieving the desired aesthetic appeal.

How Long Should Quality Leather Last?

With proper care and maintenance, high-quality leather products can last for decades, making them a worthwhile long-term value despite the higher initial price of leather goods. The durability of real leather, especially full-grain leather and vegetable-tanned leather, makes it a timeless material that often surpasses cheaper alternatives like faux leather or synthetic materials in terms of longevity and water resistance.

What Makes Designer Leather More Expensive?

Luxury brands and high-end brands typically use premium materials like full grain leather, exotic leathers, or exotic skins from exotic animals. The leather manufacturing process involves skilled craftsmen and intricate craftsmanship, following ethical standards and sustainable practices. The production cost includes everything from raw hides to the finished product, including skilled workers, ethical sourcing, and environmental impact considerations.

Is Cheaper Leather Worth Buying?

While bonded leather or lower-quality leather might be more budget-friendly initially as an affordable option, it typically represents the lowest quality among leather types and may need replacement sooner. When comparing the price varies between different types of leather, consider that cheaper leather products often cost more in the long run. For those seeking affordable prices, it's worth exploring popular alternatives that balance quality and cost, keeping in mind that the grade of leather significantly affects its durability and timeless appeal.

How Does Leather Quality Impact Functionality?

The quality of leather significantly affects both aesthetics and functionality, as demonstrated in our Bjarke Weekender bag. Using high-quality crazy horse leather allows us to create a product that weighs 5.3 lbs while maintaining durability for daily use. The leather's natural properties enable features like comfortable handles and strategic weight distribution through ergonomically designed straps. When selecting leather for functional items like travel bags, considerations must include not only appearance but also practical aspects like wear resistance and weight-bearing capacity.

Conclusion

The cost of leather products reflects a complex combination of factors, from animal husbandry to specialized manufacturing processes. While premium leather requires significant investment, its durability and timeless appeal often justify the higher price point. Understanding these factors helps consumers make informed decisions when purchasing leather goods, balancing quality with budget considerations.