Ink stains on leather items can be a frustrating problem that, if left untreated, may cause permanent damage to your valuable leather goods. This comprehensive guide explores various methods for removing ink stains from leather, ranging from commercial leather cleaners to common household items. Whether dealing with fresh stains or old marks, understanding the proper cleaning techniques and taking quick action are essential for maintaining the quality and appearance of your leather items.

Key Takeaways

- Quick action is crucial when dealing with ink stains on leather - the sooner you treat the stain, the better chance of complete removal.

- Specialized leather cleaners are the safest and most effective option for ink stain removal, but several household alternatives can work if used properly.

- Always test cleaning solutions on a small, inconspicuous area first and be gentle when cleaning to avoid damaging the leather.

- Proper drying after cleaning is essential to prevent damage from cleaning solutions, especially when using alcohol-based products.

- Following up with a leather conditioner after stain removal helps protect and maintain the leather's quality and appearance.

Introduction to Ink Stains on Leather

Ink stains are the worst. Whether it be on your leather couch, your leather bag, or other leather items. If left untreated these ink stains will probably leave a permanent mark on your leather. Covering the ink stain up is not a good option. Far worst, you do not want to throw away expensive leather just because of some stain. The best way is to clean the leather. But cleaning leather is a delicate job. You might ruin your leather more if you try to remove the ink stain. However, you need not worry. In this article, we will show you the proper method(s) of getting ink out of leather.

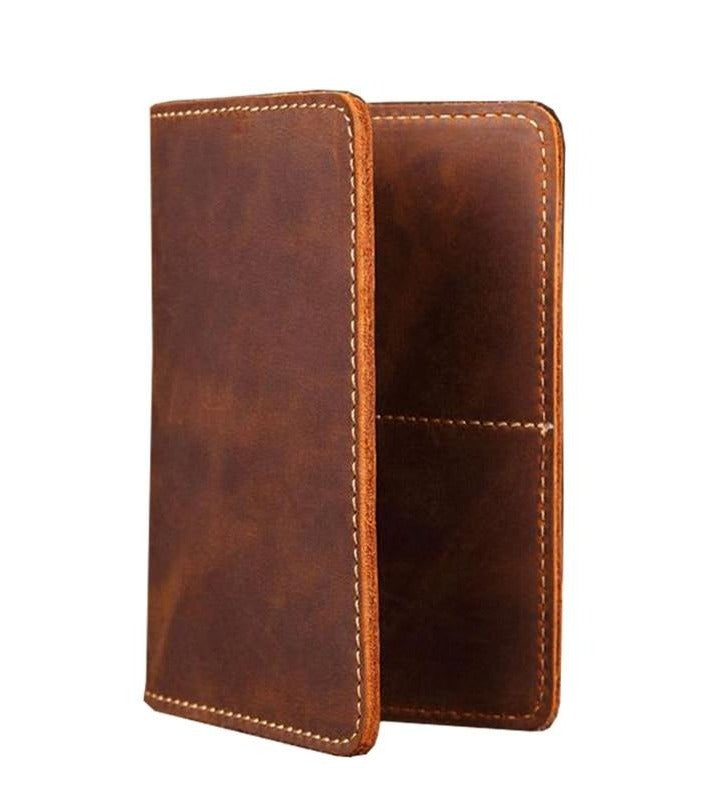

If you are the owner of a handmade leather bag, you have probably noticed that over time it takes on a beautiful aged look. This is a desirable effect and you want to retain it for as long as possible. However, there are some problems associated with this look, specifically, ink stains. So how do you fix ink stains on your leather bag? This is a much more difficult task than removing ink from clothing or other fabrics. However, it is possible to remove ink stains from leather, so long as you take the right precautions and use the right products and tools.

The Importance of Quick Action

Ink stains are difficult to remove. The longer they stay on your leather the harder it is to get rid of them. Research confirms that the sooner ink stains are treated, the higher the chances of complete removal, as fresh stains are significantly easier to handle and require less effort for effective cleaning (Ferreira et al., 2011). Therefore, it is important that we remind you that the sooner you discover the ink stain, the better. Stains are easier to remove especially when it is still fresh. They are easier to handle and require less work. Therefore, it is important that we remind you that the sooner you discover the ink stain, the better. Stains are easier to remove especially when it is still fresh. They are easier to handle and require less work.Therefore, it is important that we remind you that the sooner you discover the ink stain, the better. Stains are easier to remove especially when it is still fresh. They are easier to handle and require less work.

Handling Fresh Ink Stains

And in such a case, you may wipe the ink with a dry paper towel. Be careful not to spread the stain since it is still fresh. We suggest you dab the paper towel rather than wiping. Let the paper towel absorb the ink. Next is to use a small amount of moisturizing soap and water to clean what is left. Dry it off with a dry paper towel.

Cleaning Options for Leather

| 🧼 Cleaning Ink from Leather (Start gentlest → strongest) | ||

|---|---|---|

| 🧴 | Leather Cleaner | Best choice; use ink-specific. Moisturizes & protects. |

| 🧽 | Soap + Water | Blot fresh ink → damp cloth with mild soap → dry well. |

| 💧 | Rubbing Alcohol (70%) | Cotton swab → circular wipe → dry fast with blow dryer. |

| 💨 | Hairspray | Spray → blot immediately → soap rinse → condition. |

| 💅 | Perfume / Nail Polish Remover | Last resort; apply → wipe off → clean with soapy water. |

| ⚠️ Pro Tip: Test on hidden spot. Dry & condition after. For premium leather (Dagny Weekender, Taavi Tote), prefer specialized cleaners. | ||

It is important to understand before cleaning your leather that it is a delicate material to clean. If you use the wrong cleaning solutions, your leather may dry out and end up craking. Fortunately, for us, there are some tried-and-true methods for cleaning leather. Specifically, from getting ink out of leather. Likewise, it is fortunate for us to have a number of options. These options may range from store-bought ink removers to things that you can find in your household.

For ink stains that have been left untreated here are a couple of options for getting ink out of leather.

Professional Experience Note: When dealing with premium leather items like the Dagny Weekender, which features an ultra-soft leather handle and sophisticated design, we recommend starting with the gentlest cleaning method first. The bag's full-grain leather construction responds best to specialized leather cleaners, though mild soap solutions can be effective for fresh stains.

Option 1: Leather Cleaner

This the best option there is. If a leather cleaner is readily available we suggest you choose to clean your leather with this first. Moreover, there are leather cleaners that specialize in removing ink stains. Studies have found that specialized leather cleaners tailored for removing ink stains not only clean effectively but also provide necessary moisturization, which helps maintain the integrity of leather items, making them a superior choice over generic cleaners (Stern et al., 1987). We highly suggest you choose one that is made to remove ink stains over regular leather cleaners. However, if there are none, regular leather cleaners are still safe to use.

Option 2: Soap And Water

Some stains are not as tough as others. Just like a fresh stain, you may remove ink stains just by using soap and water. Likewise, use a dry paper towel to soak up or remove the ink. Then use a damp paper towel and moisturizing soap and gently wipe the leather clean. Be sure to dry the leather once you are done. You may continue these steps until all the ink stains are gone.

Option 3: Rubbing Alcohol

When dealing with ink stains on leather, there are several effective methods for removal. The next option in how to get ink from leather is to use isopropyl alcohol. Research has shown that isopropyl alcohol at a concentration of 70% can achieve over 90% cleaning efficacy when used to immediately clean contaminated surfaces (Datta et al., 2018). This cleaning solution can clean almost anything, though care should be taken with delicate finishes. For this ink stain removal method, you will only need three household items: rubbing alcohol, fresh cotton swabs, and a blow dryer. When treating ballpoint pen ink stains on your leather furniture or leather couch, the first step is to apply the alcohol to the ink spot. You may either apply it directly or use a soft cloth with the alcohol and then wipe it on the stain in a circular motion. For stubborn stains, you may need more than a few cotton swabs for this project. Continue this cleaning method until you remove all traces of ink. The next step is to dry the leather surfaces as quickly as possible to prevent permanent damage. Studies indicate that allowing cleaning solutions, particularly alcohol-based ones, to remain on leather surfaces for extended periods can cause damage, making immediate drying essential (Vayısoğlu & Öncü, 2021). We suggest you use a blow dryer because it is easy to use and promotes good air circulation in almost every household. This last step is crucial for leather care. While alcohol-based cleaners may clean most anything, they will have an adverse effect if left too long on different types of leather.

Option 4: Hairspray

This option for removing ink from leather is easy to use; however, it is not the most environmentally friendly among leather cleaners. According to others, hairspray is great not only for style but for cleaning leather items as well. Simply spray the ink-stained area until it is fully saturated. You may then use a dry paper towel or microfiber cloth and blot the area immediately. Be sure you soak up all the hairspray to avoid sticky residues. This will breakdown the ink mark making it easier to clean. You may finish the process by applying warm water and mild soap solution. Always make sure to dry your beloved leather items thereafter and apply a leather conditioner to protect the material!

Option 5: Perfume Or Nail Polish Remover

Finally, we have perfume or nail polish remover (acetone-based) as leather cleaning solutions. When mild dish soap and water, rubbing alcohol, or hairspray are not readily available, you may use either of these as your last option for treating leather stains. Again you may use a cotton swab, a clean paper towel, or a lint-free cloth. Apply the solution on the stained area of your leather upholstery. Gently wipe off the stain and the cleaning solution as best as you can. For safest option, you may clean it with soapy water. We need to make sure that no harsh chemicals are left on the leather surfaces. Otherwise, it would dry and damage your quality leather products.

For particularly challenging ink removal situations, especially with pigmented leather or aniline leather, consider consulting a professional cleaner. Regular cleaning and applying a leather protector can help prevent future stains on your leather furniture and maintain its beauty for years to come.

During the development of our Taavi Tote, we encountered various scenarios that helped us understand the importance of proper leather care. Made from premium crazy horse leather, this 13.4" x 13" x 5.9" tote requires specific maintenance to preserve its natural beauty. When customers inquired about ink stains on their totes, we developed a comprehensive care guide, as each bag's unique patina and slight color variations make stain treatment particularly important.

Final Reminders and Best Practices

When dealing with ink stains on leather, there are several crucial points to keep in mind to ensure the best possible outcome while protecting your leather items. Here are the essential reminders:

Important Guidelines

- Be sure to be as delicate as you can in removing the stains.

- Make sure to clean the area of dust and grime before proceeding to clean the stain off. A little dusting and wiping will do.

- Besides the leather cleaner, these options may possibly harm your leather. Therefore, always wipe off any excess.

- If possible, apply the leather conditioner after you remove the ink stain. This will not only moisturize the leather but will also give it an additional protective layer.

Why Trust Our Leather Care Expertise?

At Steel Horse Leather, our deep understanding of leather care comes from years of hands-on experience crafting premium leather goods. Our master artisans have dedicated their lives to perfecting their craft, developing an intimate knowledge of leather's properties, behaviors, and maintenance requirements. This expertise isn't just theoretical – it's built on daily work with various leather types and countless interactions with customers seeking to preserve their leather investments.

Our commitment to leather quality begins at the source, where we meticulously vet our leather providers and understand every step of the tanning and treatment process. This comprehensive knowledge of leather composition allows us to provide precise care recommendations that protect your leather items without compromising their integrity.

When we recommend cleaning methods for ink stains, we do so with a thorough understanding of how different leather types react to various cleaning agents, backed by years of testing and real-world application in our workshop. Moreover, our experience in crafting products like our vintage leather bags has taught us the importance of proper leather maintenance. We've developed our cleaning and care techniques through extensive testing on different leather finishes, from full-grain to crazy horse leather, ensuring that our advice preserves both the functionality and aesthetic appeal of your leather goods. This hands-on expertise enables us to provide practical, tested solutions that effectively address common issues like ink stains while maintaining the leather's natural beauty and longevity.

Frequently Asked Questions

How Soon Should I Treat an Ink Stain on Leather?

The sooner you treat an ink stain, the better chance you have of removing it completely. Fresh stains are easier to handle and require less work. Immediate treatment with a dry paper towel using a dabbing motion is recommended for fresh stains.

What Is the Best Method for Removing Ink from Leather?

A specialized leather cleaner designed for ink stain removal is the best option, as it both cleans the leather and provides moisturizing protection. If unavailable, alternatives include soap and water, rubbing alcohol, hairspray, or nail polish remover, though these should be used with caution.

Can Household Items Safely Remove Ink from Leather?

Yes, several household items can remove ink stains, including rubbing alcohol, hairspray, and nail polish remover. However, these methods should be used carefully and followed by immediate drying to prevent damage to the leather.

Why Is Drying Important After Cleaning Leather?

Drying is crucial because cleaning solutions, especially alcohol-based ones, can damage leather if left too long on the surface. Using a blow dryer or thoroughly wiping the area dry helps prevent potential damage to the leather.

Should I Condition the Leather After Removing Ink?

Yes, applying a leather conditioner after stain removal is recommended. This helps moisturize the leather and provides an additional protective layer, helping to maintain the leather's quality and prevent future damage.

Conclusion

While ink stains on leather can be challenging to remove, they don't have to mean the end for your valuable leather items. With the right approach, proper techniques, and careful attention to leather care, most ink stains can be successfully removed while preserving the integrity and beauty of the leather material.

References

Datta, P., Kaur, M., Rawat, S., Gupta, V., & Chander, J. (2018). Stethoscope, "the friendly foe" – a study to evaluate bacterial contamination of stethoscopes and disinfection practices. The Journal of Infection in Developing Countries, 12(10), 887-893. https://doi.org/10.3855/jidc.10128

Ferreira, M., Almeida, M., & Freitas, F. (2011). Formulation and characterization of leather and rubber wastes composites. Polymer Engineering & Science, 51(7), 1418-1427. https://doi.org/10.1002/pen.21643

Stern, F., Beaumont, J., Halperin, W., Murthy, L., Hills, B., & Fajen, J. (1987). Mortality of chrome leather tannery workers and chemical exposures in tanneries. Scandinavian Journal of Work Environment & Health, 13(2), 108-117. https://doi.org/10.5271/sjweh.2073

Vayısoğlu, S., & Öncü, E. (2021). The use of cleaning products and its relationship with the increasing health risks during the covid‐19 pandemic. International Journal of Clinical Practice, 75(10). https://doi.org/10.1111/ijcp.14534