The process of making leather is divided into several stages, beginning with raw material preparation and ending with final inspection and export. The process of making leather hasn't altered all that much over the last few thousand years. Making leather is a time-consuming and complex procedure that must be carried out with precision and attention in order to create high-quality leather with the same finish every time. The path begins with an animal hide and ends with a piece of leather ready to be changed into a leather bag, garment, or other leather product. Modern tanneries are clean and safe, with ample natural light. Automation has sped up the process, made it more efficient, and allowed for greater quality control.

Key Takeaways

- leather making is a complex process that combines traditional methods with modern technology, ensuring quality and consistency in the final product.

- There are three main types of tanning methods: vegetable, chrome, and combination tanning, each producing leather with distinct characteristics.

- The dyeing process is crucial for achieving desired colors and can significantly impact the leather's final appearance and quality.

- Modern tanneries emphasize efficiency and sustainability through automation and recycling practices.

- Proper maintenance and care can significantly extend the life of leather products.

Leather Making Throughout History

The history of leather making is as rich and varied as the material itself. Dating back thousands of years, ancient civilizations like the Egyptians, Greeks, and Romans utilized leather in myriad ways – from armor and clothing to accessories and shelter. The techniques used were often rudimentary, relying heavily on natural methods for tanning and preservation. As societies evolved, so did the processes; for instance, the introduction of vegetable tanning around 5000 BC marked a significant advancement, utilizing organic materials such as tree barks and leaves to treat hides. Leather became a symbol of status and craftsmanship, with these processes refined over generations. The Industrial Revolution led to mass production and introduced chrome tanning, drastically changing the scale and speed of leather production. Today, combining heritage techniques with modern technology not only preserves the art of leather making but also meets contemporary demands for sustainability and innovation.

Research has shown that these ancient tanning methods laid the groundwork for modern leather processing, with vegetable tanning around 5000 BC representing a pivotal advancement that blended traditional practices with innovations in material usage, demonstrating an evolution in both functionality and artistry in leather craftsmanship (Saravanabhavan et al., 2003). The Industrial Revolution's introduction of chrome tanning transformed the industry dramatically, with this method now accounting for a significant proportion of global leather production due to its ability to produce durable leather quickly and cost-effectively, though it has also raised important environmental considerations (Rao et al., 2002; Bhavya et al., 2019).

The Science Behind Leather Production

The science behind leather production is an intricate interplay of biology, chemistry, and technology. At its core, the process begins with the unique protein structure of animal hides, which is crucial to leather's durability and flexibility. During tanning, various chemical reactions transform raw hides into stable leather by cross-linking collagen fibers, thereby preventing natural decomposition. This is achieved through the use of tanning agents like chromium salts, which create an effective barrier against environmental degradation. Additionally, advances in material sciences have led to innovative tanning techniques that prioritize sustainability, such as vegetable tanning, which employs natural plant-based substances. These scientific principles not only enhance the resistance and lifespan of leather but also influence its aesthetic qualities, texture, and overall performance. Understanding these concepts is vital for appreciating the craftsmanship that goes into each leather piece, reflecting the perfect balance between nature and human ingenuity. Recent innovations in green chemistry have introduced enzyme-based dehairing processes and plant-based tanning agents that significantly reduce chemical use and environmental pollution while enhancing the biodegradability of byproducts (Thanikaivelan et al., 2003; Zhang et al., 2016). Additionally, researchers have explored incorporating organic materials like chitosan to enhance antimicrobial properties in vegetable-tanned leather, improving both product longevity and aligning with consumer demand for eco-friendly materials (Udkhiyati & Silvianti, 2019).

Raw Material Processing

Skin material may be manufactured from practically any animal's skin, including pigs, sheep, goats, and crocodiles. The most frequent hide used, however, is that of a cow. The technique of manufacturing leather employs skins that would otherwise be discarded as a byproduct of the meat and dairy industries. Rather, the animal's skin is transformed into a beautiful and useful material that will last for decades by creating leather.

Initial Hide Processing

Hides are delivered to the tannery and housed in a Beam House. They are preserved by being packed in rock salt, folded, and kept on pallets for up to 30 days. Desalting eliminates salt from the hides when they are ready for processing by tumbling and driving the hides ahead with a series of pegs. The salt is recovered and recycled in the Beam House for extra hide preservation.

Hide Preparation

Haired hides are not desalted but instead soak for one to two days in soaking drums to rehydrate and remove dirt, salt, and certain soluble proteins. Hides are treated with lime at the same time to eliminate hair and soften and improve the hide. Following that, all skins are defleshed to remove any excess waste from the rear of the hides.

Tanning Process

After the hide has been prepared, the second stage in the leather-making process is known as tanning, and it is responsible for converting the hides into leather by conserving the material and slowing decomposition. By conserving and preventing the deterioration of the hide, primary tanning turns pre-tanned hides into leather. Hides are placed in a tanning drum with chromium salts or vegetable tanning chemicals and cycled for up to eight hours.

Basic Tanning Steps

The salts and tanning compounds both preserve and soften the skin material. This ingenious piece of machinery constantly reheats the tanning solution, allowing for the finest possible penetration of the hides. Following that, fat liquoring adds natural bovine oils to the skin material, giving it strength and suppleness. The skins are then shaved to a certain, consistent thickness specified by the quality of the finished leather product. After shaving, the skins are measured to assure precise thickness.

Types of Tannage

| Feature | 🩻 Chrome-Tanned | 🌿 Vegetable-Tanned |

|---|---|---|

| Process time | ~24 hours | 4 weeks – 18 months |

| Feel & flexibility | Very soft & supple from day one | Firm at first → breaks in beautifully |

| Patina | Little to none | Rich, deep patina over time |

| Water behavior | Highly water-resistant Doesn’t stain easily |

Darkens with water (water spots) Classic “wet molding” possible |

| Dyeing & color stability | Takes dye perfectly Color stays true |

Colors can shift/fade in sun |

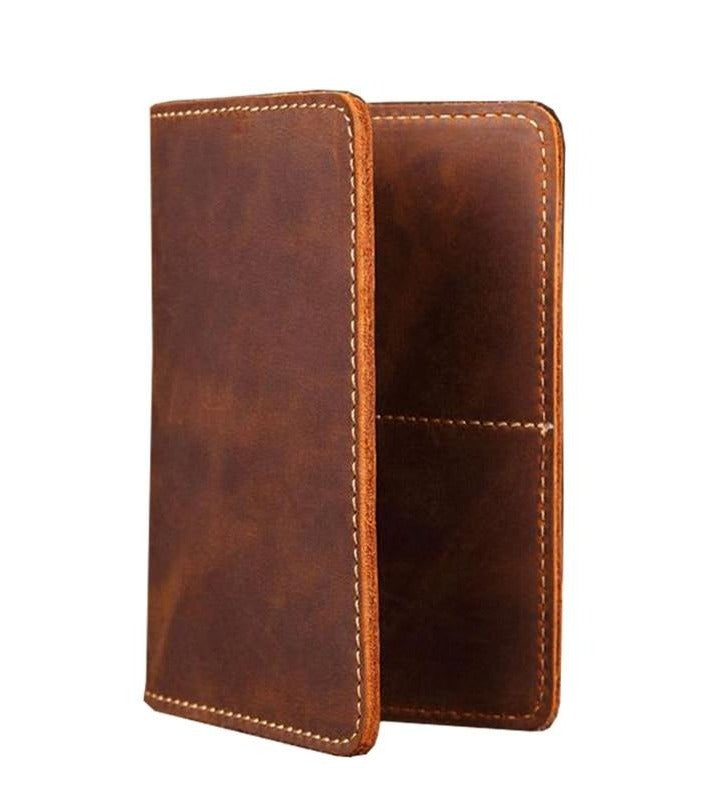

| Typical uses | Upholstery, car seats, most fashion bags, jackets | Heirloom bags, belts, wallets, saddles, journals |

| Environmental impact | Higher (chromium waste) | Eco-friendly (tree bark tannins) |

| Price | Cheaper & faster production | 30–100 % more expensive |

| 🎯 5-Second Decision Guide | |

|---|---|

| Want soft + water-resistant + consistent color → Chrome | |

| Want heirloom piece that ages like whiskey → Vegetable | |

| Daily bag you’ll beat up → Chrome | |

| Bag you’ll hand to your kids → Vegetable | |

Chrome Tanning Method

Tanners utilize a range of compounds to tan hides, as previously stated. 'Chromium' is the most often used tanning agent. It's a 24-hour procedure that yields a very stable, malleable, and long-lasting product. The bulk of leather produced globally is chrome-tanned since it is the fastest and most efficient method of tanning. chrome-tanned leather is made by tanning it using chromium sulfate and other chromium salts. Because of the faint blue tint of the undyed leather, it is also known as "wet blue."

Vegetable Tanning Method

Vegetable tanning, which is considerably older, is slower than chrome tanning. Furthermore, as the name implies, the tanning chemicals are of vegetable origin, in the form of tannin from trees and plants. Vegetable-tanned leather can be pit- or drum-tanned. The hides are placed in 'pits' with pulped tree barks and stirred for a month or more during the pit tanning process. This allows the tannins to gradually penetrate the skins. The skins also shrink slowly, which strengthens the fibers.

Comparing Chrome and Vegetable Tanning

When compared to vegetable-tanned leather, chrome-tanned leather is softer and more supple. In addition, it does not discolor or lose form as quickly in water. It's also more dye-receptive. When opposed to chrome-tanned leather, vegetable-tanned leather has more body and stiffness. As a result, the leather is more natural and matures organically like no other. However, colored vegetable-tanned leather frequently changes color when exposed to light. However, it is leather is rarely used for footwear.

Re-Tanning Process

A second tanning step may be required to thoroughly prepare the leather for its intended function. This will be repeated with either the vegetable mix or the chromium salts (or a combination), and the surplus moisture will be removed using pressure once again. The leather is then retanned to change its physical properties to fit its intended function. Leather is retanned using chromium salts, vegetable matter, or a mix of the two, resulting in a distinct hand or texture. After that, the hides are placed in a sammying machine for a second time to remove excess moisture. The skins are sorted and restored.

Drying Methods

Following that, the hides are vacuum-dried, oven-dried, or air-dried. When vacuum drying, hides are put on a level, temperature-controlled surface, and a top is dropped over them to generate a vacuum. This vacuum allows the water to be swiftly removed, resulting in a tight, smooth grain texture. When leather is vacuum dried, it shrinks by around 5%. If the air-drying process is utilized, hides are strung on an overhead conveyor that moves throughout the tannery until they are totally dry.

Dyeing Process

Dyeing gives color to the leather. Tanneries are outfitted with a variety of dyes to color leather in a range of neutrals to vivid, saturated colors. The dyeing recipe is computer-generated to assure color accuracy and uniformity. Dying leather is a time-consuming procedure. Skins are placed in dye drums for eight hours before being cut to ensure that the dye has permeated the hides completely.

Dyeing Techniques

Dyeing is the process of adding color to leather, and it is done in the drums during the tanning process. As previously stated, chrome-tanned leather is blue in color. As a result, it's frequently colored a light tan to conceal the tanning process and provide an even finish that conceals scrapes and scars. Because dye absorption varies by location, minor color changes are to be expected.

Finishing Process

When the dyeing process is finished, the final stage in the leather-making process is finishing. This is the step at which the leather will be handled to ensure that it has the supple, flexible character that is so desirable in leather, as well as the shiny finish. A coating that not only protects the surface but also makes cleaning simpler. This procedure would be bypassed if bare leather was wanted.

Finishing Techniques

The goal of finishing is to reduce the visibility of grain defects, offer the desired level of gloss, assure softness and malleability, and produce a more protected and cleanable surface. To soften the leather, skins are tumbled in temperature and humidity-controlled drums throughout the milling process. To stretch and tighten the fiber structure, hides are toggled onto stainless steel mesh frames for four to eight hours.

Faux Leather

In the nineteenth century, some of the first leather replacements were developed. Nitrocellulose (guncotton) was invented in 1845 by German chemist Christian Friedrich Schönbein and was later transformed into collodion (pyroxylin) in 1846 by French scientist Louis-Nicolas Ménard.

History and Development

Collodion was first employed as a protective covering in wound dressings, and it was later used in textiles. Fabrikoid was a pyroxylin-infused cotton fabric invented in 1910 and patented by the DuPont Fabrikoid firm in 1915. It was weather-resistant and was widely used in goods such as upholstery, book bindings, linings, and automotive coverings.

Modern Faux Leather

Artificial leather, often known as faux leather, imitation leather, and pleather, is said to have several benefits over real leather. It can mimic the look and durability of real leather at a lesser cost, and it is significantly less labor-intensive to produce. The faux leather business was predicted to be worth more than $50 billion in 2015.

Leather Preservation and Maintenance

With the passage of time, the natural fibers of leather deteriorate. Acidic leathers are especially susceptible to red rot, which results in surface powdering and a change in consistency. High temperatures and relative humidity enhance the damage caused by red rot. Despite being chemically irreversible, treatments can improve handling strength and prevent red rotting leather from disintegrating.

For instance, the crazyhorse leather used in products like The Bjarke Weekender actually improves aesthetically with use, developing a rugged, vintage appearance while maintaining its structural integrity. The bag's thoughtful design, featuring reinforced stitching and overlaid leather bars, demonstrates how modern leather craftsmanship combines durability with sophisticated design elements.

Maintenance Techniques

There are a few techniques for properly maintaining and cleaning leather items, such as using a moist cloth rather than a wet cloth or soaking the leather in water. Conditioners and other treatments are offered. Saddle soap is a leather cleaner, conditioner, and softener. Shoe polish is commonly used to condition leather shoes.

Final Inspection

The final inspection stage is a critical part of the leather-making process, ensuring that the finished product meets the highest quality standards before it reaches consumers. Each piece of leather undergoes a comprehensive evaluation where skilled inspectors examine for uniformity in color, texture, and overall finish. This stage involves checking for any defects, such as scars or imperfections that may have been overlooked during previous processing steps.

Inspectors utilize various tools and lighting techniques to assess the leather, ensuring it aligns with the specific requirements set forth by manufacturers and customers alike. Additionally, any leather that does not meet these stringent criteria is either reprocessed or recycled, reflecting the industry's commitment to sustainability. Ultimately, the final inspection not only guarantees product quality but also upholds the craftsmanship and legacy of the art of leather making.

Our Mastery in Traditional Leather Craftsmanship

At Steel Horse Leather, our expertise in leather craftsmanship spans generations of dedicated artisans who have perfected their skills through years of hands-on experience. Our master craftsmen don't just understand the technical aspects of leather making; they possess an intimate knowledge of how different tanning methods, treatments, and finishing techniques affect the final product's quality, durability, and aesthetic appeal. This deep understanding allows us to select and work with only the finest leather materials, ensuring each piece meets our exacting standards.

Our commitment to excellence extends beyond mere craftsmanship. We've invested considerable time and resources into understanding the complete leather-making process, from raw hide selection to final finishing. Through extensive research and partnerships with ethical tanneries, we've developed comprehensive knowledge of various tanning methods, their environmental impact, and their effects on leather quality. This expertise enables us to make informed decisions about sourcing and processing, ensuring our customers receive products that are not only beautiful but also environmentally responsible and ethically produced. What sets us apart is our holistic approach to leather craftsmanship.

While many manufacturers focus solely on the end product, we maintain oversight of the entire process, from hide selection to final stitching. Our artisans' deep understanding of leather's physical properties and behavior allows us to anticipate how different types of leather will age and develop character over time. This expertise is particularly evident in our selection of materials for specific products, ensuring that each item not only meets its intended purpose but exceeds expectations in terms of durability and aesthetic appeal.

Frequently Asked Questions

How Long Does The Leather Making Process Take?

The complete leather manufacturing process, which transforms raw hides and animal skin into finished leather products, can take anywhere from several weeks to months, depending on the tanning methods chosen. The leather production process begins with preparatory stages of treating raw materials. Chrome tanning, a fundamental subprocess, takes about 24 hours, while vegetable tanning using tree bark and vegetable tannins can take a month or more. Additional processes like the leather dyeing process (8 hours) and the finishing stage can add several more days to the timeline. The drying process and vacuum drying are also crucial steps in creating high-quality leather.

Is Leather Production Environmentally Sustainable?

The production of leather utilizes animal products and byproducts from the meat and dairy industries that would otherwise become solid waste. However, the tanning process involves chemicals like tonnes of chromium and water usage that require careful management under environmental regulations. Modern leather manufacturers implement recycling practices to minimize their carbon footprint. The leather industry faces challenges with chromium loads and effluent disposal units, but technological advancements have made pollution load decrease achievable through proper waste management. Studies have demonstrated promising advances in waste management, including the utilization of chrome shavings and other waste materials to develop alternative tannins, which not only reduces environmental impact but also enhances the economic viability of tanneries by creating new resources for leather processing (Rao et al., 2002; Swarnalatha et al., 2008).

What's The Difference Between Real And Faux Leather?

Natural leather is made from common hides like cow hide and other animal hide materials, undergoing a complex leather tanning process that alters the protein structure and fiber structure. This versatile material results in various types of leather, including full-grain leather, top-grain leather, and split leather. The natural grain structure creates a durable, breathable material that develops a leather patina over time. Artificial leathers and synthetic materials, including vegan leather and mushroom leather, while more affordable and requiring less manual labor to produce, may not offer the same abrasion resistance or natural properties as genuine leather products.

How Can I Tell If My Leather Is Chrome Or Vegetable Tanned?

Chrome-tanned leather, common in leather jackets and automotive interiors, is typically softer and more water resistant. Vegetable-tanned leather has more body and stiffness, making it popular for high-quality leather products like Japanese katanas sheaths. The outer layer of chrome-tanned leather often has a slight blue tint before the dyeing process. Different leather production methods result in varying qualities, from exotic leathers to semi-aniline leather, each suitable for different applications.

What's The Best Way To Maintain Leather Products?

Proper maintenance of quality leather includes using a damp (not wet) cloth for cleaning, as exposure to water can damage the leather surface. Regular conditioning with products like neatsfoot oil or mink oil is essential. The finishing process may require frequent oiling and specific products for cleaning and conditioning. To ensure the longevity of leather articles, protect them from extreme temperatures and humidity to prevent deterioration. This guide for beginners helps maintain the quality of leather goods from ancient times to modern times.

Conclusion

Finally, producing leather is a complicated process that necessitates the use of raw materials, water, and chemicals. As with bags, you should seek to get leather things that will last, both in terms of fashion and functionality. That is most likely another reason why Steel Horse Leather has become such a well-known name in the highest leather quality.

References

Bhavya, K., Raji, P., A, J., Samrot, A., Thevarkattil, P., Javad, M., … & V.V.S.S, A. (2019). Leather processing, its effects on environment and alternatives of chrome tanning. International Journal of Advanced Research in Engineering & Technology, 10(6). https://doi.org/10.34218/ijaret.10.6.2019.009

Rao, J., Thanikaivelan, P., Sreeram, K., & Nair, B. (2002). Green route for the utilization of chrome shavings (chromium-containing solid waste) in tanning industry. Environmental Science & Technology, 36(6), 1372-1376. https://doi.org/10.1021/es015635s

Saravanabhavan, S., Aravindhan, R., Thanikaivelan, P., Rao, J., & Nair, B. (2003). Green solution for tannery pollution: effect of enzyme based lime-free unhairing and fibre opening in combination with pickle-free chrome tanning. Green Chemistry, 5(6), 707. https://doi.org/10.1039/b305285k

Swarnalatha, S., Srinivasulu, T., Srimurali, M., & Sekaran, G. (2008). Safe disposal of toxic chrome buffing dust generated from leather industries. Journal of Hazardous Materials, 150(2), 290-299. https://doi.org/10.1016/j.jhazmat.2007.04.100

Thanikaivelan, P., Rao, J., Nair, B., & Ramasami, T. (2003). Biointervention makes leather processing greener: an integrated cleansing and tanning system. Environmental Science & Technology, 37(11), 2609-2617. https://doi.org/10.1021/es026474a

Udkhiyati, M. and Silvianti, F. (2019). The utilization of chitosan as natural antibacterial for vegetable tanned leather. Materials Science Forum, 948, 212-216. https://doi.org/10.4028/www.scientific.net/msf.948.212

Zhang, C., Lin, J., Jia, X., & Peng, B. (2016). A salt-free and chromium discharge minimizing tanning technology: the novel cleaner integrated chrome tanning process. Journal of Cleaner Production, 112, 1055-1063. https://doi.org/10.1016/j.jclepro.2015.07.155