Leather splitting is a crucial process in leather production, where thick leather hides are divided into multiple layers. Research indicates that the leather splitting process typically divides hides that are between 3 to 6 millimeters thick, allowing for the production of layers classified as grain, flesh, or middle splits depending on the hide's initial thickness (Nasr, 2017). This procedure typically results in a top-grain split and a flesh split, with the possibility of producing a middle split depending on the hide's thickness.

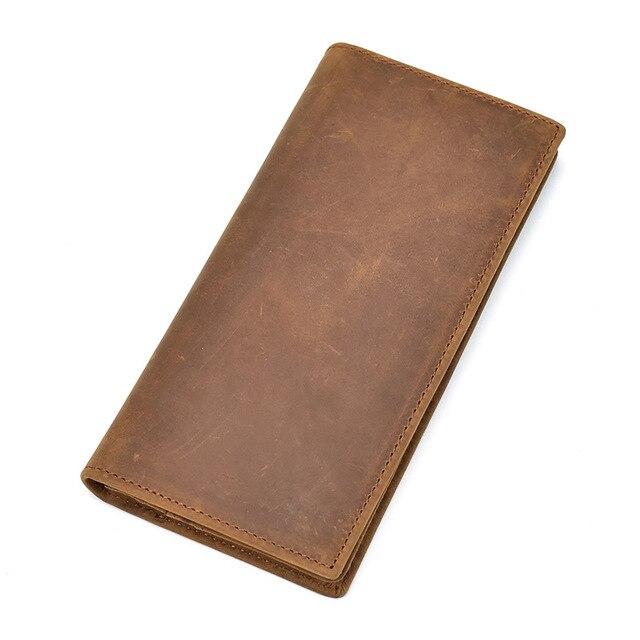

The top-grain leather, often referred to as smooth leather, is the most valuable and sought-after. It’s denser, tear-resistant, and more durable, making it ideal for high-quality leather products. On the other hand, the split leather is the softer, more fragile byproduct of this process. While it lacks the grain of top-grain leather, split leather can be used for products like suede or lower-quality leather goods.

In the leather industry, the cowhide used for splitting is carefully sorted and graded before processing. This grading reflects the animal's experiences, such as scars from bites or scratches, which can impact the quality of the final leather product. Leather consists of three primary layers: the grain, corium, and flesh. Full-grain leather, which is derived from the entire skin with minimal processing, retains the natural grain and is highly durable, making it the most valuable type of leather. Top-grain leather, though slightly more processed and smoother, is still high-quality but less durable than full-grain leather.

The split leather, which is created as a byproduct of leather splitting, is not as strong or long-lasting as full-grain or top-grain leather. However, it can still be treated and finished to resemble higher-quality leather, making it suitable for various applications. Despite its softer nature, split leather is still used in a variety of products, though it doesn’t offer the same durability or lifespan as the more premium leather types.

Key Takeaways

- Leather splitting divides thick hides into multiple layers, producing top-grain, flesh split, and sometimes middle split leather.

- Top-grain leather is the most valuable, being dense, tear-resistant, and durable for high-quality products.

- Split leather, the softer byproduct, is used for products like suede or lower-quality goods.

- Cowhides are sorted and graded before splitting, with scars from the animal’s experiences affecting leather quality.

- Leather consists of three layers: grain, corium, and flesh, with full-grain leather being the highest quality and most durable.

- Split leather is softer and less durable than top-grain or full-grain leather, but can be treated to resemble higher-quality leather.

Our Expertise in Fine Leather Craftsmanship

At Steel Horse Leather, our deep understanding of leather splitting and processing comes from years of hands-on experience in crafting premium leather goods. Our master artisans have dedicated their lives to perfecting traditional leatherworking techniques, giving us unique insights into the intricate processes of leather production and manipulation. This expertise allows us to not only create exceptional products but also to share valuable knowledge about leather quality and processing methods.

Our commitment to leather craftsmanship extends beyond mere production. We've invested considerable time and resources into understanding the complete leather supply chain, from rawhide sourcing to final processing. Through our extensive relationships with tanneries and careful vetting of leather suppliers, we've gained comprehensive knowledge of various leather types, their characteristics, and optimal processing methods. This first-hand experience with different leather grades and splitting techniques enables us to provide accurate, practical insights into the leather-making process. What sets our expertise apart is our holistic approach to leather craftsmanship.

While many focus solely on the end product, we understand that superior leather goods begin with proper hide selection and precise splitting techniques. Our artisans work daily with both full-grain and split leather, giving us practical experience with the materials and processes discussed in this article. This hands-on experience, combined with our commitment to traditional craftsmanship and ethical sourcing, allows us to offer not just products but also valuable insights into the world of leather processing and manufacturing.

Understanding Leather Splitting

Leather splitting is a process where the skin is divided into several layers over the entire surface. If the skin is divided into several layers over the entire surface, this process is called "leather splitting". The thick leather, which is 5 to 10 millimeters in thickness, is split. The obtained layers are classified as grain split or top-grain split and flesh split. There are times when the leather is thick enough for a middle split. Drop split is the difference between the split and the grain split. The leather is rough on one side and smooth on the other.

Thickness Considerations

The thickness of the skin should be taken into account when adjusting the machine because of the water content. The dry weight of leather is three times heavier than the water content of wet skin. The leather is also made thicker by this water content. The tanner needs to consider this difference in thickness when adjusting the splitting machine so that the desired leather thickness is achieved once the leather is dry.

Value and Terminology

The grain split is considered more valuable than the other two. The upper layer of the grain side has a dense fiber structure that is tear-resistant. When tanned, the grain split is referred to as smooth leather. The term "grain split" has been removed after leaving the tannery. The leather dealer uses terms such as "smooth leather", "aniline leather", and "Nappa" depending on the type of leather. The term "split" isn't connected with the grain side anymore. The drop split with the two rough sides is referred to as "split leather" or "suede" instead of being called flesh split.

Quality and Regulations

The quality of split leather is not as good as the top grain leather, so there are rules about using the terms. In almost every country there are different rules. Some countries don't allow the term "leather" to be labeled. When further details are made clear that it's split leather, some allow it to be called.

The History and Evolution of Split Leather

Split leather has a rich history that dates back centuries, evolving alongside the advancements in leatherworking techniques and the growing demand for durable materials. Originally derived from the lower layers of animal hides, split leather was often regarded as a product of necessity, utilized by artisans and craftspeople to create functional goods that required resilience. As time progressed, the tanning processes improved, allowing for the creation of a more refined and aesthetically pleasing form of split leather.

By the 20th century, with the onset of industrialization, split leather began to see a surge in popularity due to its affordability and versatility, leading to its widespread use in a variety of applications, from clothing and accessories to upholstery and beyond. Today, split leather is appreciated not only for its practicality but also for its distinct texture and character, marking it as a beloved choice for both artisans and consumers alike.

Understanding Leather Layers and Cowhide

The key to comprehending the layers of leather splitting is to first understand the layers of the leather itself. The entire thickness of the skin as rawhide is made up of three major layers. The 'Flesh' layer contains a tight arrangement of fibers on the inside, forming a tough inner skin for the animal. Corium is the intermediate layer of the hide, and it accounts for the majority of its thickness. This layer's fibers are more disorganized and open in the structure; it serves as a superhighway for skin supplies, as well as providing thickness and a cushioned barrier for the animal. The Grain is the top layer of the hide that we see on the outside; it contains the hair follicles and protects the animal from drying out making it abrasion resistant. The fibers are closely interwoven to give a particularly tough surface.

Cowhide in the Global Market

"Cowhide continues to dominate the global leather market, accounting for approximately 60% of all leather produced, highlighting its significance in leather splitting and processing (Adigüzel et al., 2022)."

Hide Quality Assessment

In order to determine the quality of the hide before it is delivered to a tanning factory, the hides are sorted and graded according to how they were affected by various factors. Was she bit by a mosquito? Was she scraped by trees or barbed wire? Or did she get brand? A hide recounts the tale of an animal's existence. They all leave their imprint on the dermis, the outermost layer of skin, although cows have a thicker dermis than other animals.

Leather Structure

As you can see in the image below, the skin has two major layers: the grain, which is at the surface, and the corium, which lies below the grain. As you approach closer to the grain or the corium, the structure of the leather changes, with fibers orientated in different orientations and natural collagen in tight or loose bundles. This has an effect on the leather's strength and character.

Types of Leather Processing

Hair-On Processing

This means the epidermis is cleansed but the fur or wool remains intact. The hide is then sent straight to tanners (more on that in the next post).

Full Grain Leather

Full-grain leather is a kind of leather that has been cleansed and tanned while keeping the animal's skin undisturbed. It's the best grade for leather splitting available. Because of the natural leather grain, it is tougher and more durable than other types of leather. The strongest fibers in leather are found in natural grain. Full-grain leather is more costly since it needs more people and costs more to produce.

Patina Characteristics

Patina is another distinctive characteristic of full-grain leather. Full-grain leather is the only leather that develops a patina. There is a tendency for it to grow along the natural grain, but it does take some time for the leather to get that wonderful old appearance.

Quality and Characteristics

Many people think (as we do) that full-grain leather is the greatest expression of leather since only the highest quality skins are used to make it. Because of this, approximately 10-15% of all leather has full grain. There's a nice, tight finish. Occasionally there may be stretch marks, creases, lines, bites, tags, or scars to give it character. When it comes to full-grain leather, there are three main reasons to preserve the distinctive grain layer with its scars and vintage appearance:

- The collagen bundles in the grain layer make it the hardest and most durable layer. It won't tear or rip.

- Its particular interaction with lubricants and sunshine makes the grain layer's surface last longer. Age and use result in a darkening ("tanning") of the leather.

- A quality wood like birdseye maple or knotty pine has a natural wood grain that may be admired for its beauty and uniqueness.

Understanding Split Leather: Quality, Durability, and Use in Products

Understanding split leather is crucial for both consumers and manufacturers alike, as it sheds light on its unique qualities, longevity, and versatility in various products. Split leather is derived from the lower layers of the hide, giving it a distinct texture and a finer grain compared to full-grain leather. This characteristic not only contributes to its beautiful appearance but also enhances its durability, making it resistant to wear and tear. Importantly, split leather is often treated and finished to elevate its aesthetic appeal further, allowing it to mimic the look of more expensive leather types while remaining cost-effective.

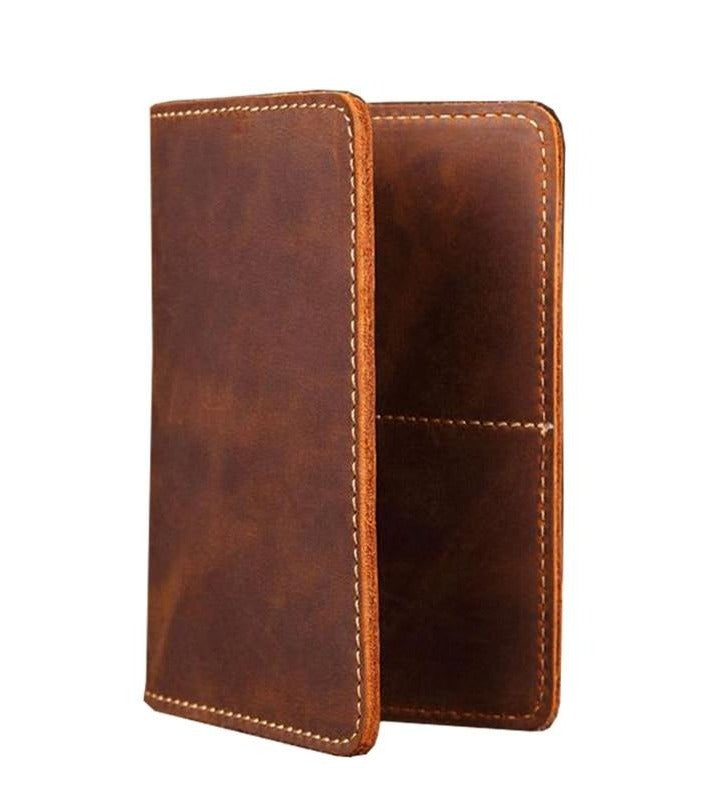

The applications of split leather are extensive, ranging from fashion accessories like bags and wallets to footwear and upholstery, showcasing its adaptability across industries. Understanding these aspects of split leather enables consumers to make informed choices, ensuring they select products that meet their quality and performance expectations.

In our experience developing premium leather goods, such as The Dagny Weekender, we've learned that the choice of leather quality significantly impacts the final product's durability and aesthetic appeal. By exclusively using full-grain leather for this weekender bag, we ensure superior durability and a natural patina development that enhances its character over time. The bag's construction demonstrates why full-grain leather is the preferred choice for high-end travel accessories, featuring both a comfortable leather handle and a removable shoulder strap that showcase the material's versatility.

Recent advances in split leather treatment have shown promising results in enhancing its mechanical properties. Studies have indicated that treatments applied to split leather, such as polymerization of acrylates, can significantly improve tensile strength and tear resistance, which are crucial characteristics for ensuring product durability (Xu et al., 2016). These innovations in processing techniques demonstrate the potential for split leather to achieve higher quality standards while maintaining cost-effectiveness.

Advanced Leather Types and Processing

Top Grain Leather

These days, the majority of leather products (including leather furniture) are made from cowhide or cow skin. This is due to the fact that cowhides are widely accessible, large, and of exceptional quality. Similar to that, cowhide is used to make much of the top grain leather we see today. Leather, on the other hand, may originate from a variety of sources, including pigs, sheep, deer, horses, and kangaroos. Then there are the unusual leathers that may be found in animals such as alligators, ostrichs and elephants.

Characteristics and Quality

As a matter of convenience, top grain leather is generally made from cowhide. Furthermore, we can refer to top grain leather as "genuine" or "true" leather, just as we do with full-grain leather, pure aniline leather, semi-aniline leather. This type of leather has had its top layer sanded removed, which eliminates scars and blemishes from lower-quality hides but also removes the leather's most resilient outer layer. As a result, the leather's lifespan is reduced. Top grain leather has a looser structure than full-grain leather, making it more flexible, and the surface does not age well. An even, constant pebble pattern may be seen on the surface of the leather. This can be easily replicated by machine stamping lesser leathers, though.

Split Leather

"Split" leather is made from the corium of top-grain or full-grain leathers that has been "left behind" (or "split"). As a result, the fibers lay flat, are more prone to break, and rest in layers. Numerous terms are used to refer to this type of hide: genuine hide, split hide, corrected hide. As a matter of fact, nubuck is top-grain leather with a treatment that makes it supple like suede.

Processing and Appearance

However, suede's suppleness comes from the tiny raw threads left behind after splitting. Producers may emboss, stamp or imprint real leather to make it appear like anything they want it to look like while it is in its natural condition. If you want it to seem like full-grain, you may cover it. So that the grain seems like top grain, it can be embossed. Debossed with a distinctive design, it can take on the appearance of an ostrich or crocodile, for example.

Bonded Leather

It's a kind of particleboard for leathers, and it's what producers do with all the leather dust that's been sanded off. "Manufactured upholstery material that incorporates animal hide" is another name for reconstituted or mixed leather. Using rubber and adhesive, the leather dust is mixed with other materials and attached to a paper or cloth background. What it is, in essence, is a cloth that has leather dust.

Characteristics and Uses

In spite of the fact that it utilizes the full hide, it takes a lot of glue and chemicals to keep it together. Because of this, it's not very long-lasting. For example, its surface can be embossed with a design, stamped, painted, printed, or debossed. Sheets or rolls of any size may be manufactured, thus their dimensions are not limited by the animal's silhouette, which is particularly useful for upholstery.

Leather Splitter Machine Technology

As a result of the original hide's thickness, it may really be divided into two layers that can be used separately. As a result of the use of a terrifying machine called a Splitter, the leather may be separated horizontally, ripping the top from the bottom to produce two identical but thinner portions from a single piece. "Full-grain leather" is created by combining the Grain and Split layers.

In modern leather goods manufacturing, precision splitting is crucial for creating high-end products like The Bjarke Weekender. During the development of this premium weekender bag, our craftsmen utilized advanced splitting techniques to achieve the optimal thickness for different components. For instance, the laptop compartment required precisely split leather that was thick enough to provide protection while remaining flexible enough for daily use. The handles, which needed to support up to 5.3 lbs (2.4 kg) of weight, were crafted from leather split to specific dimensions to ensure both durability and comfort.

Historical Development

A new technique of working with our hides was created with the introduction of the splitting machine. Preceding this, all leather was thinned by hand, using a razor-sharp stainless steel blade to systematically remove ultra-thin layers from the back (flesh side), much like planing wood. However, the splitter not only revolutionized this time-consuming and labor-intensive procedure, but it also offered us 'split leather' or 'bovine splits,' as cow skin.

Machine Operation and Results

To ensure a perfectly flat surface on both sides of a full-grain piece as well as the Split's new top, the splitting machine cuts beautifully. This means that you can now use the Split in the same way as leather, but there is one major difference: it is much more fragile now that the grain has been removed. To be functional, leather splitting must maintain the right thickness since it lacks the grain layer's tight fiber structure and is therefore considerably less robust.

Surface Treatment and Applications

An embossed grain pattern can be added to the PU finish to make the Split seem like full-grain leather by applying a thick layer of pigment on the surface, or a plasticized paint or polyurethane (PU) finish. As soon as the electric splitting knife machine was invented, school satchels were the first mass-produced splits. By the 1950s, every schoolchild had one. Currently, anything from satchel leather to convincing saffiano or croc-prints that are nearly indistinguishable from the genuine thing is available, but only when fresh.

Corrected Leather Processing

These lesser-grade skins, while not entirely split, have their uneven full-grain surface rubbed off and possibly grain- or pattern-embossed before being coated, to achieve a totally uniform surface. As the name suggests, this is a process used to extend the usability (and increase the price) of lower-quality skins by masking defects in the grain. So, while corrected leather retains part of its surface grain (and consequently some of its strength), it is completely covered up and will not polish and patina as naturally full-grained leather may.

Types of Leather Splitter Machine

While the leather splitter machine's principal job is to split leather, there are three sorts of leather splitter machines that you're likely to discover on the market today. Industrial leather splitting machine, Standard Leather Splitting Machine, and Handheld Splitter Machine are the three options.

The Industrial Leather Splitter Machines

In terms of size, industrial leather-splitting machines are those that are large enough for industrial use. These are the leather splitter machines that are more powerful. In comparison to other splitter machines, industrial leather splitting machines operate in an automated fashion. In addition to being more powerful, industrial leather splitter machines can split leather of all widths and thicknesses, and they are considerably more expensive.

Features and Requirements

With industrial leather splitters, the most noticeable aspect is that many of the functions and parts are automated instead of the hand cranks and manual feeding operations of other splitters, which are utilized for huge projects. Since the industrial leather splitter machines will also be powered by electricity, upgrading your workshop's power source could be necessary. As a result of the increased power consumption, you will also want a larger workspace, as these are not your typical tabletop machines.

Saves Time and Resources

There is no doubt that the leather splitter machine saves a lot of time. If you have a lot of tasks to work on, physically splitting leather may be a hassle. For example, using an automatic leather splitter machine allows you to quickly and easily thin down each individual portion of your finished product to a suitable thickness, ready for final assembly.

Reuse Leather Scraps

For those who work with thicker hides, you may find that mounds of leather scrap accumulate in your workstation. If you're lucky, you'll find a few bits of uneven, very soft, or extremely thick leather that you can reuse. With the leather splitter, you can convert all those leather scraps into usable leather and manufacture profitable things out of it. If you want to utilize the leftovers for little scrap crafts for yourself or for sale, you can simply separate the scraps into usable pieces. Whatever scraps you have, level them down to a nice, even thickness, and Voila! You're done! You can use them for items like wallets, key fobs, coasters, and a whole host of other crafts.

Remove Fuzziness on Flesh Side

Heavy vegetable-tanned leathers are prone to fuzziness. Leatherwork is unprofessional because of the additional fuzzy strands on the flesh side or underside of the leather. A leather splitter machine is one of the best ways to get rid of significant fuzziness in leather, even though there are alternative methods. In order to prevent the fibers from getting fuzzy again, you must apply a coat of Tokonole leather finish to the split side and buffing the surface using a leather glass burnisher.

Additional Benefits

- Reduce Amount of Glue Usage and Improves Adhesion: Glue absorbs more from leather that has a fuzzy flesh side. In the process of splitting leather, extra fibers are removed from the flesh side of the leather, where glue is typically placed. Afterwards, a tiny amount of glue may be applied to a big leather area uniformly.

- Reduces Weight from your Project: Using leather that is heavier and thicker will assist maintain the object in form while constructing items such as bags. If you're working on a project like a leather wallet, you'll need to measure every element. When designing a wallet, you don't want it to be large before the user can put anything in it.

- Remove Variations in Tannery Split: Because leather is a natural material, it gets split during tanning because it will not be perfectly flat after tanning. It is also beneficial to further thin the leather before use in order to get rid of any flaws and thickness differences.

How to Clean, Care, Store, and Repair Split Leather

| How to Care for Split Leather 🛋️ | |

|---|---|

| 🧼Clean | Wipe with damp cloth → dry cloth. Use leather cleaner for stains. |

| 💧Care | Apply conditioner regularly to prevent cracking. |

| 🗄️Store | Cool, dry, no sun. Use breathable cotton bag. |

| 🔧Repair | Scratches: rub with conditioner. Tears: see a pro. |

Cleaning, caring for, storing, and repairing split leather is essential to maintain its durability and appearance. To clean split leather, gently wipe it with a damp cloth to remove dirt and dust, followed by a soft, dry cloth to absorb any moisture. For deeper stains, use a specialized leather cleaner that's safe for your specific leather type. To care for split leather, apply a leather conditioner periodically to keep it moisturized and prevent cracking. When storing split leather items, keep them in a cool, dry place away from direct sunlight, ideally in a breathable cotton bag to avoid moisture buildup.

In case of damage, minor scratches can often be repaired using a soft cloth and some leather conditioner, while larger tears may need the expertise of a professional repair service to restore the leather to its original state. Regular maintenance is key to extending the life of split leather goods, so incorporating these practices will ensure they remain beautiful for years to come.

Frequently Asked Questions

What Happens When a Hide Is Hair-On?

When a hide is hair-on, the epidermis is cleaned and left intact along with the fur or wool and the grain, and the hide goes straight to the tanning process.

What Is Aniline Leather?

Aniline leather, semi-aniline leather, and pigmented leather. Among the three, aniline is considered as the "untouched" leather. From raw animal skin to leather, nothing is done to the material. No corrections were made to the skin. It, therefore, has the most natural form among all leather types. Making it the best type of leather available. Likewise, it is soft and gracefully supple. It can however get quite expensive.

What Is Split Leather?

This leather is the corium that has been "split" – or left behind – from the grain of top-grain or full-grain leathers.

What Is the Difference Between Suede and Leather?

(Incidentally, nubuck is a top grain leather with a finishing that makes it soft like suede.) Suede has been marketed as a luxury, high-end product, but suede's softness is nothing more than the delicate, raw, loose fibers left behind after splitting.

What Is Cowhide Leather?

Cowhide is the most common leather, comprising 67% of leather produced globally.

What Is a Hide?

A hide tells the story of an animal's life: where she got bit by a mosquito, scratched by a tree or pierced by barbed wire, or where he was branded.

What Is Bonded Leather?

The particleboard of leathers, bonded leather is what manufacturers do with all the leather dust that got sanded from top-grain and genuine leathers.

How Do I Use a Leather Splitter Match?

It's often operated by pulling on a hand crank, lever, or thumb screws, that engages the blades for the splitting action.

How Do I Measure Leather Thickness?

You will simply split using your splitter machine, measure with a leather thickness gauge, and continue to split and measure till you achieve the thickness of your choice.

Conclusion

No one can deny that split leather does not have the same qualitative qualities as top-grain leather. As long as the end-user cannot tell the difference between the two types of split leather, it is OK to coat the split leather to look like grain leather. As a result, the leather looks and feels like a veneered wood. An embossed technique creates the grain in the upper layer of leather that has a smooth leather optic.

So from the end-perspective, the user's labeling requirements are reasonable and appropriate, and leather splitting should be explicitly and clearly stated. Large machinery is used to break the hide while it is still wet in the tannery's tannin. These devices can only split tiny portions of hides and are commonly seen in leather workshops.

References

Adigüzel, F., Tosun, C., Zengin, G., & Zengin, A. (2022). Grain characteristics comparison of different types of shoe upper leathers. Proceedings of the International Conference on Advanced Materials and Systems. https://doi.org/10.24264/icams-2022.iii.1

Nasr, A. (2017). Influence of some mechanical finishing processes on manufactured leather properties. Majalah Kulit Karet Dan Plastik, 33(2), 99. https://doi.org/10.20543/mkkp.v33i2.3139

Xu, W., Zhou, J., Wang, Y., & Shi, B. (2016). Modification of leather split by in situ polymerization of acrylates. International Journal of Polymer Science, 2016, 1-7. https://doi.org/10.1155/2016/7460572