We all know for a fact that leather is beautiful. Other than its unique patina, how do we turn leather into something equally mesmerizing? A technique that people use to give the leather a bit of style is tooling. Tooling leather is what you may commonly see on book covers, wallets, belts, holsters, and other leather goods. They are those fascinating detailed ornamental works that you see on leather. While almost all types of leather can be tooled, tooling leather is the best leather for the job. Let us get to know more about tooling, tooling leather, the process of tooling, and many more.

Key Takeaways

- Vegetable-tanned leather is the best choice for tooling due to its workability and ability to hold detailed designs

- Proper moisture content is crucial for successful leather tooling - the leather must be appropriately cased before working

- Basic tooling can be accomplished with minimal tools, making it accessible for beginners

- Regular maintenance and protection from elements are essential for preserving tooled leather items

- The quality of tooled leather work depends on three factors: proper leather selection, appropriate tools, and skilled technique

Historical Evolution of Tooling Leather

The historical evolution of tooling leather can be traced back thousands of years, intertwining with the development of various cultures and their artisan skills. Initially, early civilizations utilized animal hides for practical purposes, such as shelter and clothing. Over time, skilled craftsmen began to recognize the potential of leather as a medium for artistry, leading to the refinement of techniques that are still in use today.

Ancient Egyptians, for instance, created embossed and dyed leather goods, while the Romans honed their tooling techniques, producing intricate designs that adorned armor and accessories. As leatherworking spread across Europe, each region introduced its unique styles and motifs, influencing the diverse array of tooling methods seen in contemporary practices. Today, tooling leather is not only a representation of functional artistry but also a celebration of historical craftsmanship, bridging the gap between past traditions and modern design.

Understanding Tooling Leather

What exactly is tooling leather? To answer that questions we must first get a few things straight. We must first understand the difference between tooling and tooling leather. Tooling is the process of engraving or embellishing designs on leather. Tooling leather on the other hand is the leather that we use to make those beautiful designs. Think of tooling leather as the canvas. Conclusively, tooled leather is the leather that has gone through the tooling process or creative design.

Types and Characteristics

Tooling leather can be any leather available. However, they generally use vegetable-tanned leather. Of all the types of leather, why would they prefer vegetable tanned leather? The answer is quite simple. Unlike other methods of tanning, the vegetable tanning process produces leather that is a bit softer and easier to work with. Research has shown that vegetable-tanned leather retains impressions better than chrome-tanned alternatives, which tend to prioritize flexibility over definition in detailed crafting (Romer et al., 2011). Likewise, since you are trying to etch designs onto the leather, you would generally need softer leather.

Thickness Variations

Moreover, tooling leathers also come in different thicknesses. The thickness of the leather will vary from one project to another. For example, a belt will require a thicker cut of leather than a knife sheath or wallet. Likewise, different layers of leather can also be glued together to create thick leather. These are usually for designs that require more thickness than the normal cut.

Comparison of Tooling Leather with Other Leathers

When considering what is tooling leather, it's essential to understand how it compares with other types of leather. Tooling leather, which undergoes the natural tanning process known asvegetable tanning using natural tannins from tree bark, is specifically designed for creating intricate designs and detailed designs. Unlike chrome-tanned leather processed with chromium salts, which produces soft leather that's more pliable, high-quality tooling leather boasts a firmer texture and greater resistance to deformation during detailed work.

Additionally, its ability to retain sharp impressions means that artisans and leather craft enthusiasts can achieve beautiful designs that stand the test of time. The art of leather tooling allows for both geometric designs and floral designs using essential tools like a swivel knife and stamping tools. In contrast, regular leather and chrome leather may prioritize soft touch and comfort over durability for carving, making them less suitable for leather projects requiring ornate details. Full-Grain Leather and Top-Grain Leather serve different purposes, but for leather tooling skills development, proper preparation of the leather surface is crucial.

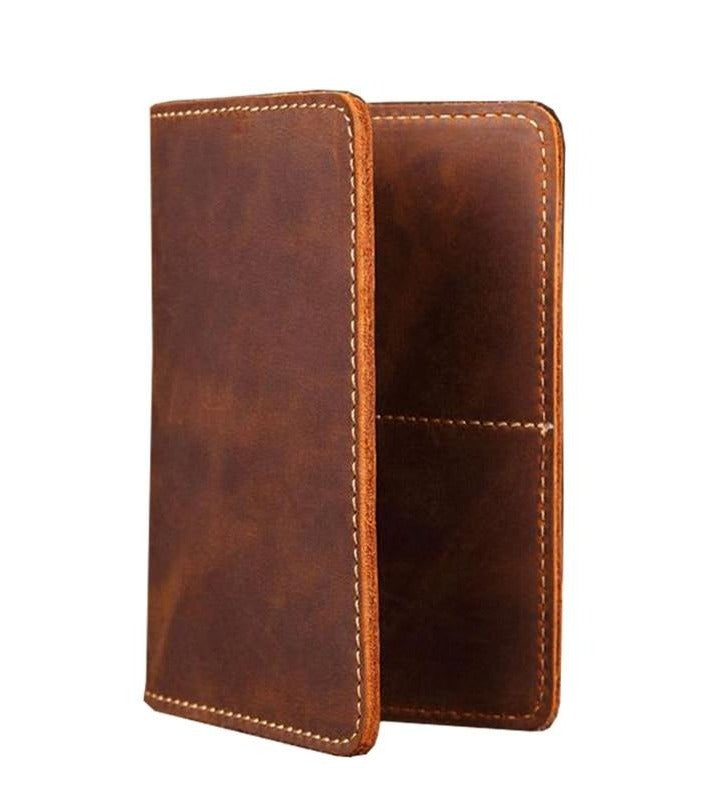

This versatile material is perfect for creating custom leather items such as leather wallets, leather belts, and decorative panels. With the wide array of leather working tools available and proper leather conditioner application, craftsmen can achieve a beautiful patina on their leather creations. Thus, for anyone engaged in the art of tooling leather, choosing the right piece of tooling leather is crucial to achieving the desired aesthetic appeal and functional outcomes in their leather crafting journey.

Preparation and Working Process

To create those beautiful designs and patterns we need to prepare the leather. While technically any leather can be tooled it does not produce the best result. This is because some types of leather are too stiff to cut with leather stamps and tools. Likewise, we would not want leather that is too soft, flexible, or bouncy that it erases the stamp impressions. What we need is a type of leather that is soft enough for cutting yet firm enough for stamping. This leather is vegetable-tanned leather.

Moistening the Leather

To work with vegetable tanned leather we must first prepare. The preparation process is pretty simple. In order for the leather to be workable, it needs to be moist. What better way to moisten leather than to use water. This process of moistening the leather is what we call casing. Wetting the leather will make the fibers swell and soften. This step is necessary for us to shape and manipulate the leather's surface.

To work with vegetable tanned leather we must first prepare. The preparation process is pretty simple. In order for the leather to be workable, it needs to be moist. What better way to moisten leather than to use water. This process of moistening the leather is what we call casing. Wetting the leather will make the fibers swell and soften. This step is necessary for us to shape and manipulate the leather's surface. Studies have demonstrated that applying water evenly to both sides of the leather enhances its responsiveness to tools and prevents damage to the material during the engraving process (Zhang et al., 2018).

To moisten the leather we rub a damp sponge on both the flesh side and the grain side of the leather. It is important that we apply the water evenly as possible on both sides.

Leather Selection for Different Techniques

Leather for tooling, carving, and engraving can be any type of leather. However, if we just use any type of leather for tooling and carving, the results will likely vary. Tooling needs to be done on leather that is soft enough to cut and carve, but firm enough for stamping. Vegetable leather is therefore what many consider the best leather for tooling and carving. It possesses the characteristics and quality that allow us to manipulate leather surface easily. Moreover, vegetable-tanned leather also maintains certain features even after a sharp object has been forced over it.

Achieving Good Results

To obtain good results there are certain things that need to be done. First, you must have the right leather for the job. While it is true that you can use other types of leather for tooling, vegetable-tanned leatherwork is considered to be the best. Moreover, it is easier to work with, especially for beginners.

Next is to have the proper leather working tools. Without the proper leather tools, manipulating the leather's surface would be a very difficult task. It may not also turn out as great as you want it to be if you do not have the proper tools. There are various tools that we use in tooling leather. Each tool has a unique function that will affect the surface differently.

Lastly, you must possess the proper skill and knowledge in tooling leather. Research confirms that the success of a tooling project depends on three key factors: appropriate leather selection, the right tools, and the craftsman's skill, with each aspect significantly influencing the final outcome (Romer et al., 2011). You may have the right tooling leather and the right tools but if you do not know what you are doing then what is the point.

Understanding Leather Engraving and Embossing

Leather craft is not only a profession but can also be a hobby. For the untrained eye, it is sometimes difficult to tell the difference between leather engraving and leather embossing. For those who are not familiar with leather crafting, engraving and embossing may look the same. While it is true that they bring more life and character to the material, both, in a way, are different.

Key Differences

The main difference between engraving and embossing is the procedure. To get those beautiful patterns, embossing uses a machine called presses. The machine engraves a pattern on the leather by applying heat and pressure to the surface. Embossing is usually done if you want uniform designs on the leather. It is also widely used in mass processing because it is easier and faster. Embossing is, therefore, a mechanical way of leather crafting.

For leather engraving, we use our hands. No machine, just tools, skill, and a lot of practice. Maybe a little bit of sweat here and there. Leather engraving is a long process in comparison to embossing. It takes time to perfect. Most of the time, its designs are left to the creativity of the craftsman. Unlike embossing where the pattern is predetermined. It may therefore come out as unique in a way. Leather engraving also offers great satisfaction once you master it. It, likewise, makes a great hobby!

The Process of Leather Working

To engage, tool, or carve a leather hide you will first need the right leather. The starting leather material that many generally use is "crust leather". It is usually a semi-finished full grain hide whose surface is still in the natural stage. At this stage, the hide or leather is perfect for engraving.

Initial Preparation

To start the process, the hide or leather needs to be moist. It is important to moisten the leather so that its fibers become ready for tooling. Moreover, it is only when the surface is moist where you can carve the leather. Once the leather dries out, it would be difficult to manipulate the leather's surface. You can, however, just re-apply water to the leather's surface from time to time, or for as long as the project takes. It is also important to remember that you must apply or moisten the surface as evenly as possible. We usually apply or moisten the surface by rubbing it with a damp sponge.

Tools and Techniques

Once the preparations are complete, you are now ready to engrave, tool, or carve the leather hide. There are different techniques that you can apply. Many patterns and textures are also available to carve on the grain side of the hide. However, you must have the proper tools to properly engrave, tool, or carve the leather. These tools are not that expensive. Likewise, there is no need for you to spend a fortune on tools. Just have the right tools for the right job and you will be fine. Some people only need a swivel knife, a background tool, and a hammer.

Appearance and Characteristics

Since we generally use vegetable tanned leather as tooling leather, its appearance will largely depend on the whole tanning process. Vegetable tanning uses natural tannins that come from leaves, branches, the bark of trees, and plants. This natural process of tanning produces natural earthy colors like browns, beiges, yellows, and even red. Vegetable tanning also produces a distinctive smell on the leather. The leather usually has a sweet, woody fragrance. Something that you normally associate with real leather. It also produces a unique set of shades and other nuances on the surface, making it look and feel genuine.

Common Applications and Uses

Since engraving, tooling, or carving leather is typically by hand, its use is more personal. Many treat tooling leather as an ornamental item for their personal collection. Since it is a labor-intensive process, it is generally expensive. Its price is also due to the use of high-quality leather necessary and equipment for tooling. Tooling leather has many uses. From shoes to bags, belts, holsters, life sheats, clutches, wallets, and many more. As long as you use the right leather, the right tools, and creativity, tooling leather will have infinite uses!

For example, at Steel Horse Leather, we recently developed The Langley Backpack, which showcases the versatility of high-quality crazy horse leather. While this particular piece doesn't feature traditional tooling, it demonstrates how different leather working techniques can be combined to create functional art. The deep chocolate brown leather develops a unique patina over time, similar to tooled leather pieces, showing how different leather working approaches can achieve equally stunning results. During the development process, we carefully considered how the natural characteristics of the leather would enhance the bag's functionality and aesthetic appeal.

Another prime example of tooling leather's versatility can be seen in our signature Dagny Weekender bag. During its development, our artisans carefully selected premium leather to ensure optimal tooling results. The intricate detailing on the bag's exterior demonstrates the perfect balance between functionality and artistic expression. Each interior pocket was thoughtfully designed and tooled to maintain both structural integrity and aesthetic appeal. The ultra-soft leather handle required particular attention during the tooling process to ensure it would maintain its comfort while developing that coveted patina over time.

Pros and Cons of Tooling Leather

Advantages

The main advantage of tooling leather against other types of leather is that it is perfect for engraving, tooling, or carving leather hide. It is also the ideal leather for embossing designs on leather. Using other types of leather will not produce the best results. High-quality tooling leather on the other hand will produce edges that are sharper, clearer, and more well-defined. Moreover, since this type of leather is generally vegetable-tanned leather, it will develop a beautiful patina over the years. This type of leather is also strong and durable, and will typically last for a long period of time.

Disadvantages

The process of creating leather from the vegetable tanning process is slow and labor-intensive. It is also an expensive process. It likewise, requires a lot of time and a great deal of patience. Another disadvantage of tooling leather is its inconsistencies. Because it uses hides from different animals, its quality will differ greatly. Some may not be the same qualities as the other just because it comes from a different animal. Furthermore, there is no artificial protective agent coating on this form of leather. As a consequence, it's vulnerable to the elements.

Caring for Tooling Leather

Tooling leather is an ornamental item. It is personal and unique. It is likewise expensive. You wouldn't want anything as exquisite and expensive as tooling leather to deteriorate too easily. Even if the tooling is made of high-quality leather, it will need some tender loving care.

Protection from Elements

A big disadvantage when it comes to this type of leather is that it has no protective agent coating whatsoever. It is therefore vulnerable to the elements like water and the sun. It is best to avoid getting the leather wet. In case the leather does get wet, you can wipe it dry with a soft dry cloth. Allow it to dry in a cool place away from direct sunlight. Do not dry your leather by exposing it to heat or hot hair.

Cleaning and Maintenance

Of course, other than the elements, leather is vulnerable to dirt, dust, and grime. There are many ways to remove and clean them. The easiest method is to wipe it off with a damp cloth. You can also dampen the cloth with mild soap or baby shampoo. Be sure to wipe it dry after! However, since this leather has carvings on its surface, dirt, dust, and grime can get into difficult-to-reach places. Brushes are usually the right tool for the job. We recommend using animal hair brushes for cleaning. Brushes that have synthetic bristles tend to be stiff. We likewise recommend cleaning the leather at least once a week, especially if you use it often.

Finally, add leather conditioner to the leather. This will nourish the fibers while also providing a protective coating. We suggest that you wax the leather on a regular basis if you want it to stay in good shape.

Step-by-Step Guide to Tooling Leather

| Step | Action | Tools |

|---|---|---|

| 1️⃣ Prep & Transfer | Dampen leather → Trace or freehand design | Sponge 💧, Stylus ✍️ or Pencil |

| 2️⃣ Cut Lines | Trace design with swivel knife (½ depth) | Swivel Knife 🔪 |

| 3️⃣ Bevel Edges | Press down edges for depth | Beveler or Spoon 🥄 |

| 4️⃣ Add Details (Optional) | Stamp seeds, dimples, textures | Seeder 🌱 or Camouflage Tool |

| 5️⃣ Fill Background | Stamp all background areas | Background Tool + Mallet 🔨 |

Essentials: Veg-tanned leather, swivel knife, background tool, mallet, sponge & water.

We mention how leather tooling requires skill to do. However, it is a lot easier than you think. With the right tools, a little bit of guidance, and practice you can make beautiful leather carvings yourself! In fact, all you need is a few tools, vegetable tanned leather, a sponge, and some water.

Essential Tools

Once again, you do not need to spend a fortune on tools to tool leather. Especially if this is your first time or if you are new to tooling leather you might want to start small. You will essentially need a few tools. These essential tools are a swivel knife, a background tool, and a mallet or a hammer. A shader of some kind would also be a good tool to have. However, if you are not ready to invest in one or if there are none available there are alternatives. A spoon is an easiest and most common replacement.

Detailed Tooling Process

Step 1: Transfer Your Design to the Leather

Before you actually transfer the design to the leather, you must first moisten the leather with your damp sponge. Once the leather is wet enough you can start your design. Generally, there are two methods to design the leather.

The first method and probably the safest thing to do for newbies is to print out a design. Place the design on the leather ink-side up and trace the line with a stylus. A stylus is a special tool we use to trace the printout onto the leather. If there is none available you can always use a pencil or anything that will dent the surface of the leather.

The second method is to freehand the design. You may either refer to a design on the internet or get creative. Make a custom design yourself. Be sure to get the leather wet so that it will leave a dent where you run your pencil or stylus.

Step 2: Cut the Lines

After the design is clearly indented on the leather it is time to use your swivel knife. Use the swivel knife and trace along with the design. You will actually cut the leather here wherever the bold lines and edges are. A swivel knife blade is sharp, control is very important. Make sure not to cut the leather all the way through. We recommend you cut it halfway through. First-timers or those who have not had enough practice tend to make shallow cuts. That is okay, however, shallows cuts usually end up looking flat in the end.

At this point, your leather will look really nice with all those cuts and the design. However, this is just the second step. There are still a few things to do to make the leather more beautiful.

Step 3: Bevel the Edges

In this step, we will use a shader or a special beveling tool. However, a spoon is really great alternative. Use the spoon to bevel the edges that you want to stand out. This will add depth to the design and make it look even better. After beveling the cuts, we are more than halfway done.

Step 4: Add Little Cutesy Stuff

After the third step, the leather and your design will probably look like the final product. However, there are a few steps that will make the tooling leather look better. This step is not necessary and will require a specific tool for the job. If you have the tool available, then better. If you have none, it's okay, just move along to the next step.

In this step, you will need a seeder. This tool makes little circles on the leather for added design. We usually use this to add "seeds" in plants or flower designs. Another tool that you may also use is a camouflage tool. this tool makes little dimple on the leather.

Step 5: Fill in the Background

The next step is fairly simple however it is time-consuming. This is also an essential step, so you can’t skip this out. Use your background tool and stamp down all the backgrounds on your design. This will make your design really stand out, so do not hold back on stamping it down.

Step 6: Add Finishing Touches / Edits

Take a look at what you have accomplished so far. Take a look at the design, get a closer look or take a step back and see the whole picture. Make finishing touches such as cutting, beveling, or stamping.

Step 7: Finish the Leather

Finally, is to add a finishing. You can either opt not to do this since it is not really a necessary step. However, you can always add a protective layer to your leather once you are done tooling. We suggest you condition the leather and really get in the cuts and edges. This will protect the leather, especially if you don’t have time to clean it regularly.

Adding Color and Finishes to Tooled Leather

When it comes to enhancing the visual appeal of tooled leather, adding color and finishes can create stunning results that highlight the intricate designs.

Various techniques can be employed, such as dyeing, painting, or applying a finish to protect and enhance the leather. For instance, using a high-quality leather dye can penetrate the grain and enrich the natural tones, while acrylic paints allow for vibrant, artistic expressions on your leather pieces. Additionally, finishing products like beeswax or acrylic sealers provide a protective layer that not only helps to preserve the color but also adds a subtle sheen.

By experimenting with these techniques, leather craftsmen can achieve unique and personalized looks, bringing their creations to life and ensuring that each piece tells a captivating story.

Why Trust Our Leather Tooling Expertise?

At Steel Horse Leather, our deep understanding of leather tooling comes from years of hands-on experience crafting premium leather goods. Our master artisans have dedicated their lives to perfecting traditional leatherworking techniques, including the intricate art of leather tooling. This expertise is reflected in every piece we create, from our vintage bags to custom-tooled accessories. Our commitment to excellence extends beyond mere craftsmanship. We maintain direct relationships with premium leather suppliers and have extensively researched various tanning processes, particularly focusing on vegetable-tanned leather - the gold standard for tooling work. This comprehensive understanding of leather sourcing and processing allows us to select the perfect materials for tooling projects, ensuring optimal results in terms of both aesthetics and durability.

What sets us apart is our holistic approach to leatherworking. While many focus solely on the end product, we understand that exceptional tooled leather pieces begin with selecting the right raw materials and using time-tested traditional methods. Our artisans' obsessive attention to detail and passionate dedication to their craft means we can offer not just products, but valuable insights into the art of leather tooling.

Whether you're a beginner looking to start your leather tooling journey or an experienced craftsperson seeking to refine your techniques, our expertise is grounded in real-world experience and a genuine love for this timeless craft.

Frequently Asked Questions

What Is Tooling Leather And Why Is It Special?

Tooling leather is specifically designed for creating decorative patterns and designs. While any leather can technically be tooled, vegetable-tanned leather is preferred because it's softer and easier to work with, producing the best results for detailed designs.

How Do You Prepare Leather For Tooling?

Leather must be moistened through a process called casing, where water is applied evenly to both the flesh and grain sides using a damp sponge. This process makes the leather fibers swell and soften, making it workable for tooling.

What Tools Are Needed For Leather Tooling?

Essential tools include a swivel knife, a background tool, and a mallet or hammer. Additional tools like shaders can be helpful, but beginners can start with these basic tools. A spoon can serve as an alternative to specialized shading tools.

What's The Difference Between Leather Engraving And Embossing?

Engraving is done by hand using tools and requires skill and practice, while embossing uses machines that apply heat and pressure to create uniform patterns. Engraving offers more creative freedom but takes longer to complete.

How Should Tooled Leather Be Maintained?

Tooled leather should be protected from water and direct sunlight, cleaned regularly with a soft cloth or animal hair brush, and conditioned periodically. Regular waxing helps maintain its condition and appearance.

Conclusion

Leather tooling is both an art form and a craft that combines traditional techniques with creative expression. While it requires patience and practice to master, the basic principles are accessible to beginners with the right materials and guidance. By understanding the proper preparation, techniques, and care methods, anyone can begin their journey into the rewarding world of leather tooling. Whether pursuing it as a hobby or profession, the satisfaction of creating unique, handcrafted leather pieces makes it a worthwhile endeavor.

References

Romer, M., Lenting, H. B. M., & Komanschek, B. U. (2011). Vegetable tanning: A review of the chemistry and environmental impact. Journal of the Society of Leather Technologists and Chemists, 95(1), 1-8.

Zhang, Y., Liu, J., & Covington, A. D. (2018). The effect of moisture content on the mechanical properties of leather during processing. Journal of Leather Science and Engineering, 1(1), 1-12.