Skiving is slowly losing its significance and falling into obscurity as the leather crafter continues to move to a different aspect of advanced leather projects. But with skived leather, it is slowly taking back the prestige it once had. In essence, skived leather manually involves skiving leather edges by hand. This edge refers to the edge of leather items that require a skiver, as mentioned above. Whether it’s a belt, bag, wallet, or jacket, skiving edges are essential in ensuring the durability and aesthetic appeal of your work of art. Luckily for you, skived leather manually has become easier than ever before thanks to modern technology. In this blog, we will tell you everything you need to know about skived leather and what options are available for your entire leather pieces.

What is Skived Leather?

Skived leather is an actual leather type that has been split down the middle, then glued back together. This process results in stronger and more durable leather than regular leather. Skived leather is often used in luxury goods such as handbags, shoes, and belts. The durability of skived leather makes it a viable alternative to conventional leather in many applications. Skived leather isn’t new; craftspeople have used it for centuries. Its versatility makes skived leather an appealing option for consumers of all backgrounds and budgets.

Types of Skiving: Options That Work

Skiving refers to cutting the leather to create various textures and patterns. Skiving can be done in different ways, such as diagonal skiving (which creates a criss-cross or wale look) or checkerboard skiving (where the leather is cut into small squares). The type of skiving you choose will depend on the look you are trying to achieve for your leather piece. For example, pebble grain skiving creates a rugged texture that looks great when used on boots and jackets. However, diagonal skiving is best used for leather parts that require subtle texture, such as handbags and shoes.

As you can see, skiving has great versatility and allows you to create a variety of looks with the same piece of both hard and soft leather. It’s an essential step in creating high-quality pieces of leather goods that will last through years of wear and tear.

The Perfect Time to Skive

As stated above, skiving is a type of leather processing that involves shaving the leather down to the grain, preserving the natural look and feel of the leather while providing a more durable surface. Skiving is most commonly used for products that require a high level of durability and resistance to wear and tears, such as outdoor sports equipment, fashion accessories, and automobiles. In this case, skiving offers an economical and efficient way to produce a product with a grained surface finish that is both highly functional and appealing. However, skiving can be time-consuming, so it's important to choose skived leather products made from quality materials.

Reasons for Skiving Leather

Skiving leather helps improve the water resistance of leather products and makes them more comfortable to wear in the sun. In addition, skiving adds flexibility and softness to leather, making it easier to clean and maintain. Lastly, skiving allows for the creation of vivid colors that can add character and interest to a piece of leather craftsmanship. Overall, skiving is a creative way to improve the durability and comfort of your leather items.

100% Glue Adhesion | Skived Leather

One of the biggest advantages of skiving leather is its 100% glue adhesion. This ensures that the skived leather will not move or come unstuck during use. As a result, the finished product will always maintain its shape and look consistent and smooth.

Increased Durability | Skived Leather

One of the main benefits of skiving leather is that it provides increased durability at a lower cost than other types of leather. This makes skiving leather a smart choice for applications that require a high degree of wear and tear. Besides, skived leather is often used for products such as shoes, bags, and clothing due to its durability and resistance to wear and tear.

Make Stitching so much Easier | Skived Leather

Skived leather is a process of cutting the leather into thin sheets using a variety of sharp blade options. This process creates a much smoother contact surface that is less likely to tear or crack during the stitching process. For this reason alone, skived leather also makes stitching easier, as there is no need to stitch through the layers of leather.

Help to Accessorize Leather | Skived Leather

One of the biggest advantages of skived leather is that it requires less work on the part of the leatherworker. Instead of hacking away at the hide with knives and chisels, skived leather requires only a simple skiving operation. This reduces the amount of time required for production and results in more efficient use of resources.

Leather Consistency and Uniformity | Skived Leather

The process of skived leather involves splitting the skin lengthwise and shaving off the layers, which produces a uniform and consistent product that is easy to handle, which makes leather easy to handle and less likely to tear.

Better Appearance | Skived Leather

Skived leather is a process that makes it more desirable and appealing by giving it a smoother finish and often different patterns or colors. The top surface of skived leather can be rough to the touch, which provides it with a better appearance and texture. It also allows for the use of different colors and patterns on the surface of the leather. Overall, skived leather is an efficient way to improve the visual appeal and functionality of leather products.

How Do You Skive Leather Edges?

Switching to skived leather can help improve the durability of your leather products and make them last longer. Besides, skived leather edges are a cost-effective alternative to traditional leather edge treatments, making it an easy and profitable choice for many industries and consumers as there are a lot of skiving tools that can be used.

Using a Leather Skiving Knife

The quality skiving knife has a curved skiver blade type attached to a wooden handle that is specifically designed to shave the outer edges of the leather. Leather skiving knives can be bought in different sizes and shapes, and they come in different materials, such as stainless steel and carbon steel. Depending on the type of leather you are skiving, you may need to use a skiving knife of a specific width, thickness, or the bevel angle of the leather itself. If you are planning on creating products from leather, it is always helpful to research and purchase a quality skiving knife for the job.

Using a Leather Skiving Machine

When skiving the edges of the leather, you will need a leather skiving machine. This leather skiving machine uses a series of rotating cutting blades, which are among the common blade shapes, to create the desired skived edge. The process is relatively simple and can be completed in minutes. It is important to use a quality leather skiving machine to ensure a precise finish, the perfect example of this is the Consew DCS-S4 Leather Skiving Machine. You could end up with an uneven or jagged edge if you're using an improper tool.

Using a leather skiving machine will result in an improved look and durability of your leather goods, making them more appealing and functional. Whether you are creating accessories, wallets, bags, or other items, skiving leather edges is essential to creating a professional and stylish appearance.

Using a Manual Leather Skiver

The skilled use of leather skiving results in edges of leather that are smooth and even, making it easy to create products from the material with precision and accuracy. Skived leather edges manually require a steady hand and careful attention to detail in order to create uniform, sharp edges. It is an art form that requires patience and practice to master.

Using a Tabletop Skiver

This tool is made from high-quality steel and has a sharpened blade square that allows you to easily cut the leather. Before using a skiver, you must first determine the size of the leather edge you need to skive. Once you’ve determined the size of its edges, place the leather on a flat surface and place the edge of the skiver against it. Next, press down firmly with your hand to ensure that the extra blade is against the leather and start skiving. You can use a skiver in multiple different ways to get the perfect edge: by placing it against one end of the leather piece, then moving it up one side, and finally down the other side; or by placing it near one side of the piece before moving it to another location.

Doing Manual Leather Skiving Like A Pro

Skiving is a time-consuming and labor-intensive process. Although it requires some experience, it can be done by anyone with basic sewing and craft skills. If you’re interested in learning how to do manual leather skiving, it’s a great idea to check out our guide!

Start Right By Being Prepared With The Right Leather Tools

If you're considering doing leather skiving yourself, be prepared with the powerful tools and supplies. Thicker leather requires a special type of skiver called a skiving knife or cutter. This type of skiver has a serrated edge that is used to cut the leather without damaging the surface. To ensure effective skiving, the edge of a skiving knife should be sharpened regularly. In addition, a vise to hold the leather while it's being skived, as well as clamps or a band saw to remove the excess leather, are useful tools for leather skiving.

Doing Manual Skiving Accurately

A leather skiving knife is essential for accurate and consistent results. You also need a piece of leather that is the right size for the job. If you want to become a master at skiving leather, practice on some scrap pieces before tackling your favorite jacket or pair of shoes.

Conclusion

In the above blog, we showed you the various reasons for both hard and soft leather skiving and the different methods used for both easy and heavy leather crafting. We also made sure to tell you that there is no such thing as one-size-fits-all skiving. It is all about understanding the leather type, thickness of leather, and desired finish of the leather (if any), along with the leather skiving machine used by the craftsman!

FAQs

Is there any difference between quality and price in terms of skived leathers?

There is a significant difference in quality and price between skived leathers. The higher the excellent quality of the leather, the more expensive it will be. By paying attention to the grade of leather (i.e. cowhide, steer hide, etc.), you can ensure that you're getting the best possible product for your money.

What are the steps involved in creating skived leather?

To create skived leather, the steps involved include scouring and conditioning the leather, applying a coating of wax or resin, and skiving the leather, which is the process of cutting the leather into thin strips.

What types of leather can be used for skiving?

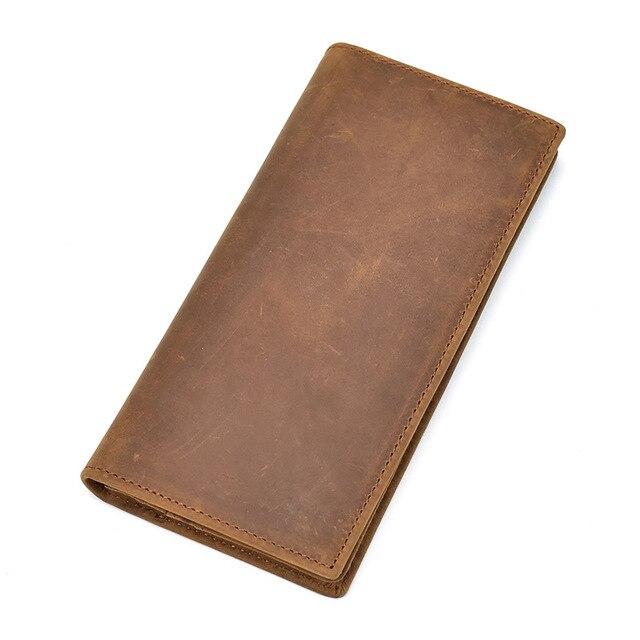

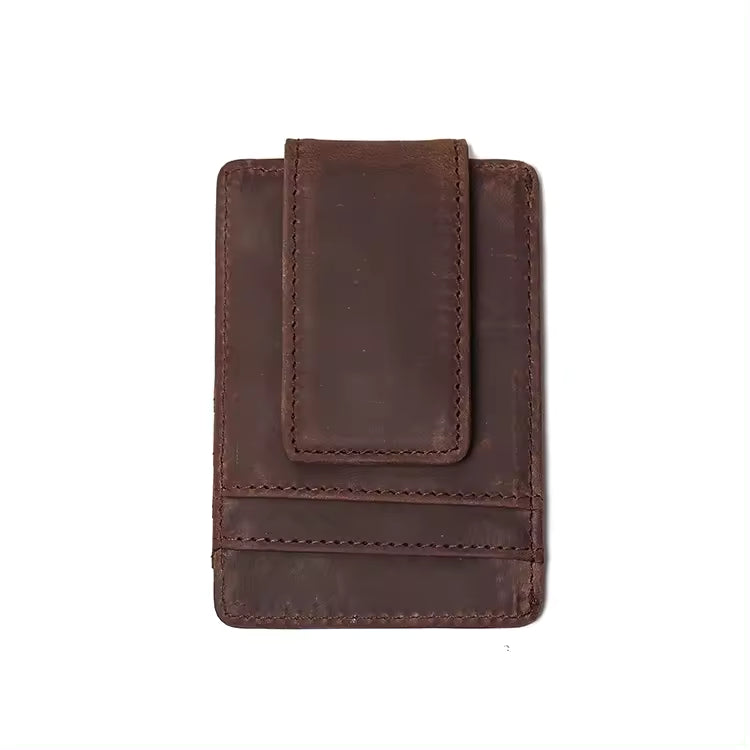

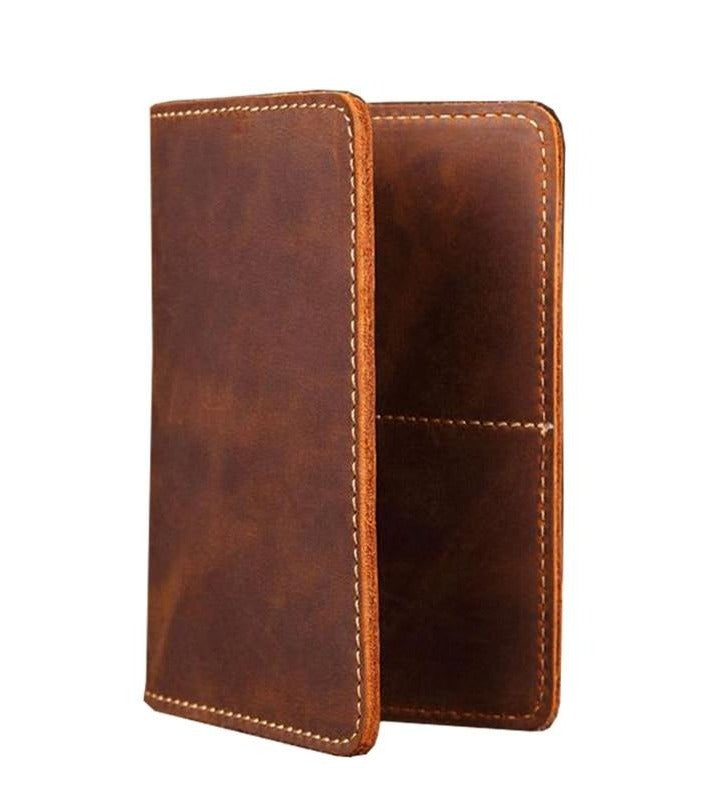

Skiving is an ancient craft that has been used for centuries to create different types of leather products. Leather can be skived from different types of skins, such as cow, pig, and sheepskin, as these are used to create different types of leather products and accessories, such as shoes, bags, and wallets.

What are the benefits of skived leather?

There are various benefits of skived leather, the most notable of which is its durability and flexibility. So, if you're looking for a new type of leather product to add to your wardrobe, skived leather is a great option to consider.

What are some potential problems with skived leather?

Some potential problems with skived leather include the fact that it is a type of leather that has been shaved down to its surface. This process can introduce small tears and weaknesses into the leather, which may not be as durable as full-grain leather. Additionally, skived leather may also be more difficult to clean and maintain.

Is skived leather a sustainable resource?

Yes, skived leather is a sustainable resource. Skived leather is made by scraping the skin off of an animal's back. The skin is then dried and cured. This process results in a more sustainable option than traditional leather production methods, which involve tanning the skin of cattle.