Do you love the feel of a well-crafted leather product forcorporate gifts? If so, you may be familiar with leather goods manufacturers - those manufacturers who turn out some of the most beautiful and aesthetically pleasing leather goods in the world. What are leather goods, anyway? Simply put, a leather goods manufacturer is a business that makes and sells high-quality leather products. They may specialize in leather wallets, leather handbags, leather accessories, or even furniture, among other things.

Key Takeaways

-

Leather goods manufacturers vary significantly in scale and capabilities, with small manufacturers offering limited quantities and customization options, while large manufacturers can handle bulk orders and provide extensive customization without additional costs.

-

The leather manufacturing process involves multiple critical stages including material sourcing, tanning, dyeing, finishing, stitching, and quality inspection, each affecting the final product's durability and appearance.

-

Full-grain leather represents the highest quality and most expensive option, followed by napped leather, with coated leather being the most affordable but lowest quality choice available.

-

When selecting a leather goods manufacturer, prioritize companies with strong reputations, comprehensive warranty policies, robust quality control procedures, and a commitment to customer satisfaction.

-

Leather goods offer superior environmental sustainability, durability, and protection compared to synthetic alternatives, making them a worthwhile investment despite higher upfront costs than mass-produced items.

The Welch Briefcase | Vintage Leather Messenger Bag

Our Expertise in Leather Goods Manufacturing

At Steel Horse Leather, we bring decades of hands-on experience in leather goods manufacturing to every insight shared in this guide. Our master artisans have dedicated their lives to perfecting the traditional craft of leather working, combining time-honored techniques with an obsessive attention to detail that only comes from years of passionate dedication to the art of leather craftsmanship. This deep understanding of every aspect of the manufacturing process—from raw material selection to final finishing—gives us unique insights into what truly distinguishes exceptional leather goods from mass-produced alternatives.

We don't just write about leather goods manufacturing; we live it every day. Our holistic approach to the entire supply chain, from thoroughly vetting leather providers to understanding the nuances of different tanning practices, gives us the expertise to guide you through the complex world of leather goods selection. When we discuss quality control procedures, manufacturing processes, or what to look for in a reputable manufacturer, we're drawing from our own rigorous standards and real-world experience in creating durable, elegant leather products that stand the test of time.

What is a leather goods manufacturer?

Leather goods are a luxurious and often expensive purchase. That's why it's important to choose the right maker for you. Not all leather goods manufacturers are the same, and it's important to know what to look for before making a decision. First and foremost, make sure you're looking for a maker that has a long history of producing high-quality leather goods. Additionally, research ratings and reviews from other consumers to help you make an informed decision. Once you've found the right maker, be patient as it may take some time for them to produce your order. But don't worry, it will be well worth the wait!

History of Leather Goods

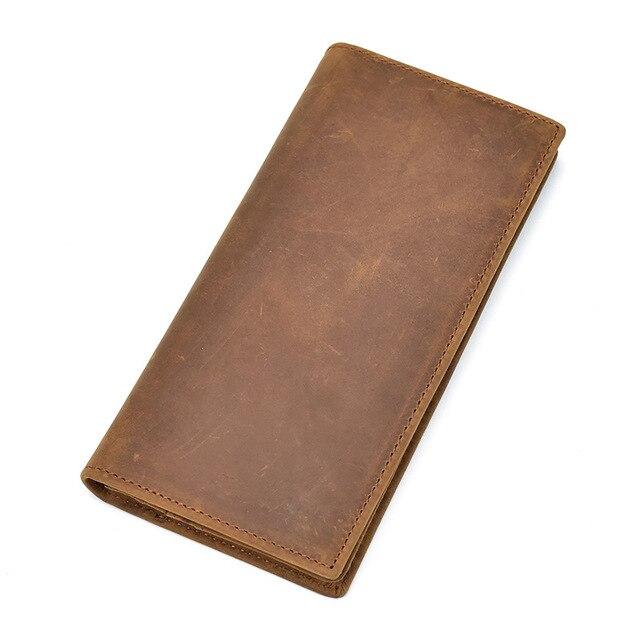

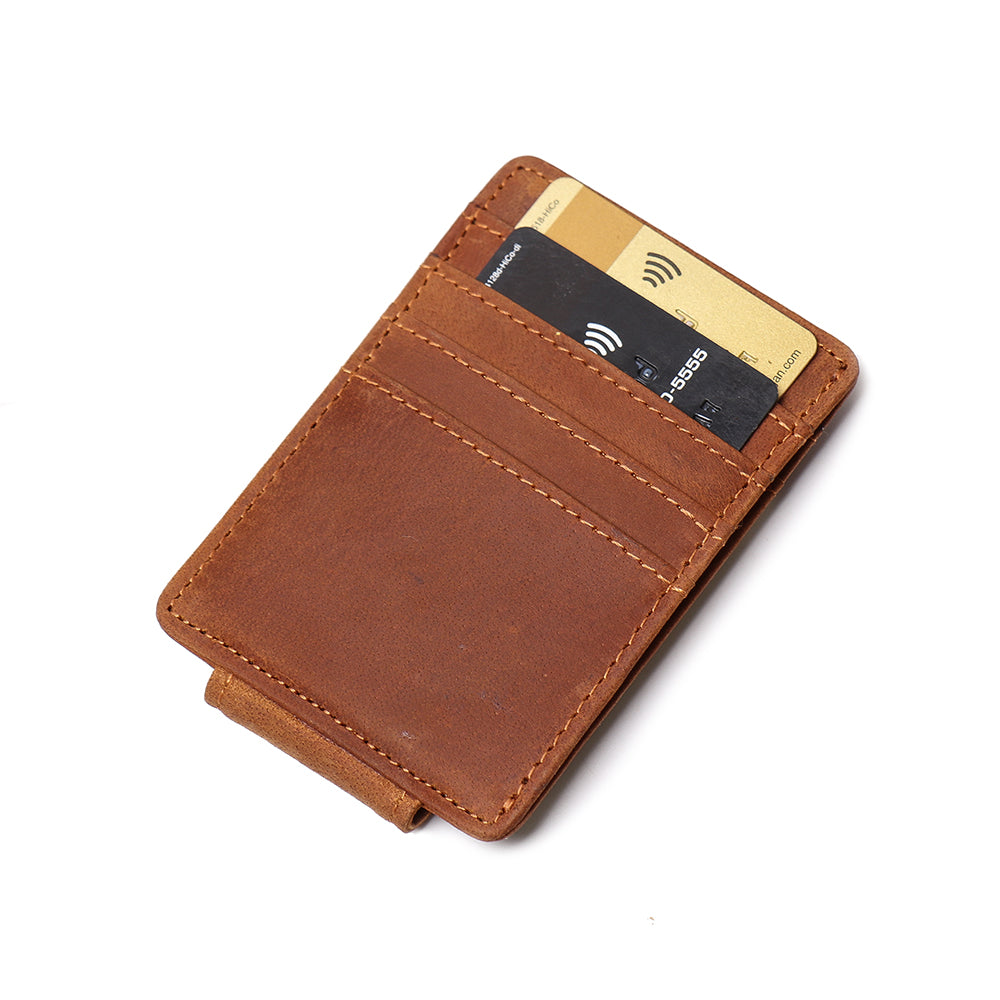

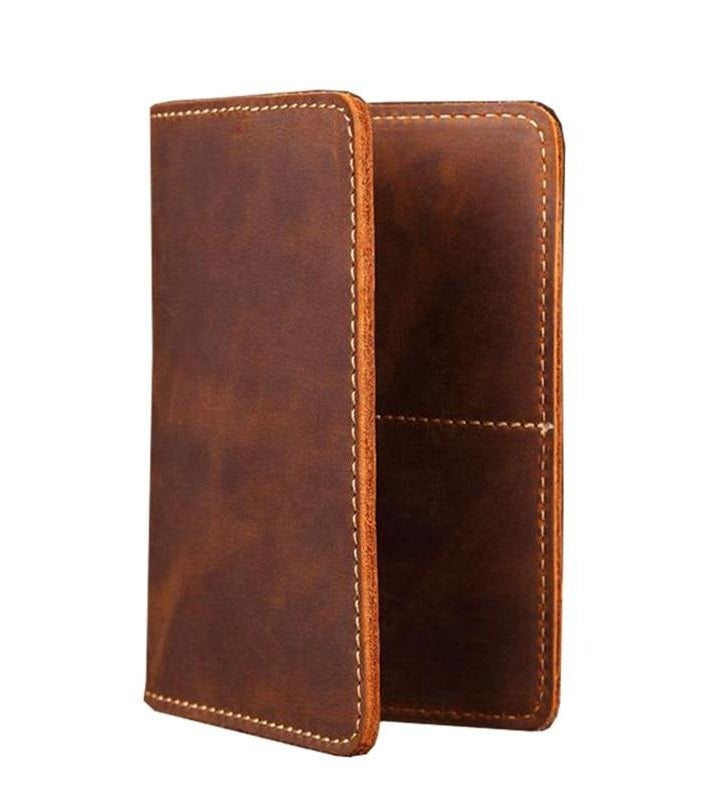

Leather goods have a long and diverse history dating back to antiquity. They are made from animal skin, usually, cattle, sheep, or goats, and can include footwear, bags like leather backpacks, leather baskets, leather wallets, leather bins, leather blanket carriers, leather bookmarks, leather bookends, leather bracelets, and leather belts, etc. Over the years, there has been a great demand for leather goods so there are many different types of leather goods manufacturers out there that emerged.

How do leather goods manufacturers make their variety of products?

Leather goods manufacturers play a vital role in the world of fashion. They manufacture various products like wallets, purses, belts, etc., and use various methods to create them. To get the best product for your money it is important to choose a leather goods manufacturer that can provide you with the right quality and price point. Make sure you inquire about their processing methods and how they make the leather goods - this will give you an idea of what kind of quality assurance they have in place.

What is the difference between a small and large leather goods manufacturer?

When it comes to choosing a leather goods manufacturer, it's important to keep in mind the scale of their production. A small leather goods manufacturer might only produce a few thousand pieces or low minimum quantities of a product while a large one can produce bulk orders. This means that they will be able to provide you with high-quality products at affordable prices. Furthermore, the difference between these two types of manufacturers is their ability to customize products according to your particular needs. A small leather goods manufacturer might not have the resources or expertise required for this so you'll have to pay extra for this service. On the other hand, a large leather goods manufacturer will be able to accommodate all your customization requests without any additional cost.

What are the different types of leather goods a manufacturer produces?

Photographer: Kelly Sikkema | Source: Unsplash

There are three main types of leather goods a manufacturer produces - full-grain, napped, and coated. Full-grain leather is of the highest quality and it is the most expensive to produce. Napped leather is second in quality and it is less expensive to produce than full-grain leather. Coated leather is the least expensive type of leather and it has a lower quality than the other two types of Leather goods.

Leather manufacturing process

Leather Manufacturing Process

When choosing a leather goods manufacturer, it is important to consider a variety of factors, including their manufacturing process, the type of leather and finishes they offer, and their ethical sourcing practices. Understanding each stage of production ensures you select high-quality products that meet your needs and style.

| Stage of Manufacturing | Description | Key Activities & Purpose |

|---|---|---|

| Animal Skin Processing | The initial treatment of raw animal skins. |

|

| The Tanning Process | Converting rawhide into a more durable, flexible, and colored product. |

|

| Dyeing Process | Adding color and patterns to the leather. |

|

| Finishing and Stitching | Assembling and protecting the leather pieces. |

|

| Inspection and Testing | Quality control checks and adding final features. |

|

When it comes to choosing a leather goods manufacturer, it's important to consider a variety of factors. Make sure to review their manufacturing processand see if it meets your needs. Some important questions to ask include: What type of leather will they use? What types of finishes will they offer? Are their products ethically sourced? Once you've answered these questions and determined that the manufacturer meets your needs, it's time to review their products. Take a look at their collections and see if any products suit your style. Be sure to ask questions during your visit and make sure you're comfortable with the answers. If you have any further questions, don't hesitate to reach out!

Animal skin is first processed

First and foremost, there is this process called material sourcing. Animal skin is first processed to remove the hair, flesh, and other unwanted material. This ensures that the skins are of high quality when it comes to producing leather goods.

The tanning process

The tanning process is the first step in leather manufacturing. It takes rawhide or leather and converts it into a product that has more durability, flexibility, and color. There are many different types of tanning processes available, each with its own benefits and drawbacks for the final product. For example, some tanneries strip the skin of its natural oils and proteins; this makes them ideal for use in products like wallets or shoes made from tough hides such as cowhide or horsehide. Depending on your particular needs, you may need to select a specific type of tanning process to reach your desired results.

Dyeing process

To create different basic colors and patterns on leather goods, the dyeing process is used. The different parts of the animal are used to extract dyes that give a specific color and range of styles to the final product. Different types of dyes are also used in this process to get desirable results.

Finishing and stitching

After dividing the pieces into their desired sections, they are then stitched together and treated with a protective coating. This process helps to ensure that the finished products are of high quality and durable.

Inspection and testing

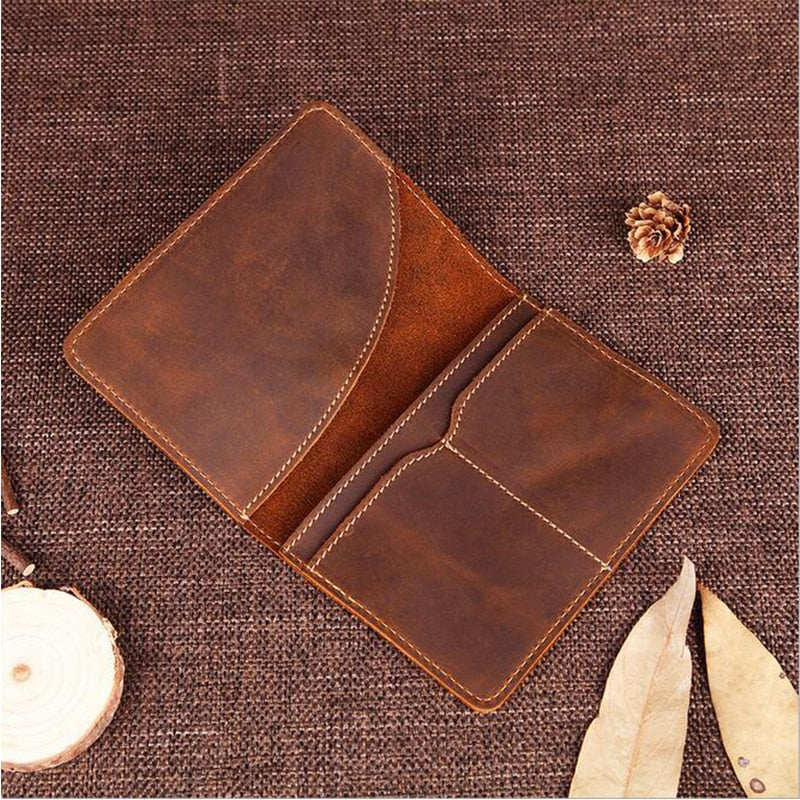

Inspection and testing are important steps in the production of leather goods. It helps to ensure that the skin - the main component of handmade leather goods - is of good quality, while also checking for any defects in the core. This is also the design phase where the finishing touches are done, such as putting straps, zippers, luggage tags, the private label, or the logo. Some even include additional features such as a paper refills compartment or money clips. Once all checks have been completed, the products will be sent for branding and finishing.

Things to consider while choosing a leather goods manufacturer

Choosing the right leather goods manufacturer can be a daunting task. There are a lot of factors to consider, from budget to types of leather available. Make sure to research the different leather manufacturers and choose the one that is best for your business. Avoid choosing a company just because they have a good reputation; carefully evaluate their services before making a purchase decision! Once you have made your choice, be sure to take the time to train your team on the manufacturer's policies and procedures. This will ensure that your products are produced to your specifications and meet your client's requirements.

Warranty and Return Policy

It is important to know about a manufacturer's warranty and return policy before making a purchase. This will help you assess the quality of the product and decide whether or not it is something that you are comfortable with. Make sure to ask about their processing time - this will give you an idea of how quickly they can get your order to you. In addition, inquire about any additional charges that might be incurred in returning the product (for example, shipping costs).

The range of leather goods offered by the company

Leather goods are a popular choice among people of all ages. In fact, there is something for everyone on the market nowadays. However, it is important to select a company that offers an extensive range of leather goods of the highest quality. Not only does this make shopping easier, but it also ensures that you get what you expect from the purchase. It's also important to take into account the construction and design of each product before making your decision; after all, you wouldn't want to invest in a low-quality item, would you? With so many options available on the market today, narrowing down your choices can be difficult - but well worth it!

Available sizes and colors

When it comes to choosing a leather goods manufacturer, it is important to consider the size and actual colors of your business. Not only will this ensure that the products you order are just right for your needs, but it will also match the branding and image of your company. There are many leather goods manufacturers that offer a wide variety of sizes and colors to choose from, so take some time to compare specifications before making an order!

Quality control procedures

Quality control is an essential part of any leather goods production process. By properly selecting a reputable manufacturer, you can ensure that your products are of the highest quality and meet all your expectations. It is important to inspect the entire production process from start to finish. This way, you can be assured of accurate measurements and correct stitching techniques. In addition, it would be wise to inquire about certifications and guarantees offered by the manufacturer. By doing so, you could minimize potential risks during product development or after-sales service

Commitment to customer satisfaction

Choosing a leather goods manufacturer that you can trust is of the utmost importance. Make sure to do your research and stay up-to-date with industry trends. Also, be sure to ask for references before making any decisions - it's always better to have multiple sources of information before committing yourself. Most importantly, make sure the leather goods manufacturer you select offers top-quality and beautiful handmade products at an affordable price - this will go a long way in ensuring nationwide or worldwide customer satisfaction. In addition, always ensure that your safety is paramount when visiting their factory or dealing with them in any other way.

The benefits of using leather goods

When it comes to leather goods, it's important to choose the right manufacturer. Not only will this ensure quality products, but it will also benefit from great customer service. The right leather goods manufacturer will use environmentally friendly raw materials and have a long lifespan that is resistant to wear and tear. Additionally, leather goods are durable and can last for many years without any repairs or replacements needed. As you can see, choosing the right leather goods manufacturer is essential for ensuring you're getting the best possible product.

Price: higher than mass-produced items but still a luxury that is affordable

Leather goods are certainly one of a kind and they come with a long list of benefits. Most importantly, leather goods last a long time - even if you wear them every day. Furthermore, they're not as expensive as some other types of products but their price is still affordable for the average person. Some popular choices include shoes, wallets, bracelets, and backpacks - all of which can be customized to your needs and preferences. In fact, it's often easier to find high-quality leather items than accessories that are mass-produced in factories. This is because the craftsmanship of the artisans involved in making leather goods is usually much more meticulous than manufacturing cheap accessories out of synthetic natural beauty of materials by average brands.

Leather goods are a timeless classic

Leather goods are a timeless classic that never goes out of style. They can be used for many occasions - from special events to everyday wear. Plus, leather goods require very little maintenance - just a bit of polish every now and then is all you need to keep them looking great.

Appearance: high-quality, unique leather goods

Leather goods are a versatile accessory that can add class and refinement to any outfit. They come in many ranges of styles and colors, making them the perfect choice for anyone who wants to stand out from the crowd. Plus, leather goods are durable and long-lasting, so you won't have to replace them often.

Environmental consciousness - leather goods are environmentally friendly

If you're looking for an environmentally-friendly material to use in your accessories, leather is a great option. Not only are its materials sustainable, but leather goods don't require a lot of chemical treatments or solvents - meaning less harm is done to the environment in the long run. In addition, they offer better protection against weathering and damage than other materials, making them an ideal choice for items that need to last. Furthermore, by choosing leather goods over cheaper alternatives like plastic bags or paper products you can actually reduce your carbon footprint. So not only are leather goods stylish and practical - but they also have environmental benefits!

Protects your belongings against water, dirt, and scratches

Leather goods are a great way to protect your belongings from water, dirt, and scratches. They are also very durable and will last for years. If you're looking for a stylish way to keep your things safe, leather goods are an excellent choice!

Frequently Asked Questions

How Can I Tell if My Leather Goods Are of Good Quality and Will Last Long?

One way to tell if your leather goods are of good quality and will last long is to look for a reputable leather goods manufacturer with established quality standards. A reputable manufacturer will use high-quality raw material and construction in their products, implementing comprehensive quality control systems throughout their production process, which should ensure that your items will hold up well over time. Additionally, expert reviewers may recommend specific brands or models of quality leather goods, including luxury brands that specialize in handmade leather goods and premium products. When evaluating leather quality, look for full-grain leather or top-grain leather, as these offer superior durability compared to other types. The craftsmanship quality is also evident in details like hardware options, italian zips, and the overall leather smells that indicate proper tanning processes.

How Does Quality Affect the Price of a Leather Product?

The quality of leather affects the price of leather goods in several ways. Higher quality leather, such as vegetable-tanned leather or full-grain and drum-dyed cow steer and buffalo leather, typically costs more than lower quality alternatives because of the time and labor involved in producing them. Additionally, higher-quality leather products may also require additional processing steps through laser-cutting machines, automated stitching, or specialized materials and finishing techniques that add to their price. Custom leather products and handmade and custom leather goods often command higher prices due to their personalized nature and the skilled leather crafting involved. Luxury leather articles from quality-centric global fashion brands also reflect premium pricing due to their design development processes and superior production management.

What Is the Best Way to Care for Your Leather Goods?

Apply a leather treatment every 6 months or so, like a conditioner. The best way to care for your leather goods is to apply a leather treatment every 6 months or so, like a conditioner. Proper maintenance extends the life of your leather garment and other leather items, whether they're made from sustainable materials or traditional leather. Even vegan leather products benefit from appropriate care routines. For those who work with leather belt blanks or wholesale leather strips, regular conditioning helps maintain the material's flexibility and appearance.

How Do You Pick the Best Leather for Your Products?

There is no definitive answer to this question, as leather sourcing depends on your specific needs. Different types of leather are suited for different products, so it can be tough to decide which type of leather is the best for a particular product. Consider factors like vegetable and chrome tanned leathers for different applications, and evaluate whether sustainable materials like recycled leather might meet your requirements. The production run size and customization options available from your supplier may also influence your choice. Pattern making requirements and the intended use of the final product should guide your selection process.

What Is the Difference Between Cowhide, Goat Hide, and Sheepskin?

Cowhide is the most common type of leather, obtained from cows and often processed into full-grain leather. Goats and sheep produce leather similar to cowhide, but their skin is less thick. Each type offers different characteristics suitable for various applications in leather goods manufacturing, from luxury designer items to everyday accessories like leather straps.

Which Types of Leather Are Used in the Industry and Why Are They Better Than Others?

The three most common types of leather are cow, pig, and deer leather. Cow leather is the strongest and has the least flexibility, but it is the most durable, making it ideal for products requiring longevity. Pigskin is a close second to cow leather in strength and flexibility, but it is less durable than cow leather. Deerskin is the weakest and most flexible of the three, but it also has the highest level of durability for its weight class. Modern leather goods manufacturing also incorporates sustainable production methods and may utilize scrap materials to reduce waste while maintaining quality standards.

What Types of Treatments Should I Use on My Own Leather Goods Before Selling Them or Giving Them as Gifts?

There is no one-size-fits-all answer to this question, as the type of treatment required will depend on the individual item(s) being treated. However, general recommendations for treating leather goods include using a conditioner or oil, applying a coat of sealant or wax, and occasionally rubbing them with a grained wooden stick. For those involved in custom product manufacturing or working with hand-made products, proper finishing techniques are essential. Consider laser engraving for personalization, especially for special occasions like father's day gifts. Quality treatments help maintain the appearance and durability of your leather items.

What Are Some Important Factors to Consider When Choosing a Leather Goods Manufacturer?

When choosing a leather goods manufacturer, important factors to consider include the company's reputation, manufacturing processes, and quality control measures. Additionally, it is important to verify that the supplier has a good supply chain in place so that products are delivered on time and meet customer satisfaction expectations. Look for manufacturers that offer private label manufacturing services, scalable contract manufacturing facilities, and have experience working with boutique designers. Consider their turnaround times, minimum quantities requirements, and whether they provide custom product designing services. Evaluate their commitment to fair trade practices, ethical standards, and ethical labor practices. Check for certifications like iso certification or membership in organizations like the leather working group, which indicate adherence to sustainable ethical suppliers standards.

What Are Some Quality Assurance Procedures That I Should Follow When Working With a New Leather Goods Supplier?

Some quality assurance procedures to follow when working with a new leather goods supplier include verifying that the leather goods company is licensed and insured, performing an inspection of physical facilities, checking for résumés of previous owners/leaders demonstrating relevant skills and experience in the industry, and reviewing manufacturing processes. Additionally, evaluate their quality control system, examine their leather supply chain for reliability, and assess their customer service responsiveness. Consider their prototyping team capabilities, shipping timelines, and reorder times. For those requiring private label leather goods manufacturing, ensure the supplier can maintain full control over quality while meeting your specifications. Before finalizing partnerships, you may want to sign up for supplier communications or sign in to their systems to better understand their operations. Some suppliers may require moderator approval for new accounts, so factor this into your timeline. Be sure to go to topic listing areas of their websites or catalogs to understand their full range of services and capabilities. Look for suppliers that demonstrate diversity and inclusion in their practices and have experience working with mfg studio environments or similar production facilities.

Conclusion

Leather goods manufacturers are responsible for the production of high-quality leather products. They use various techniques and processes to produce products that are both sturdy and beautiful. If you are in the market for high-quality leather goods, it is important to choose a manufacturer that meets your specific needs. Make sure to read through the blog to get an understanding of the different types of leather goods available and the various methods used to produce them. Once you have found a manufacturer that meets your needs, contact them to discuss your specifications.